Jahresbericht 2005 - IPHT Jena

Jahresbericht 2005 - IPHT Jena

Jahresbericht 2005 - IPHT Jena

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

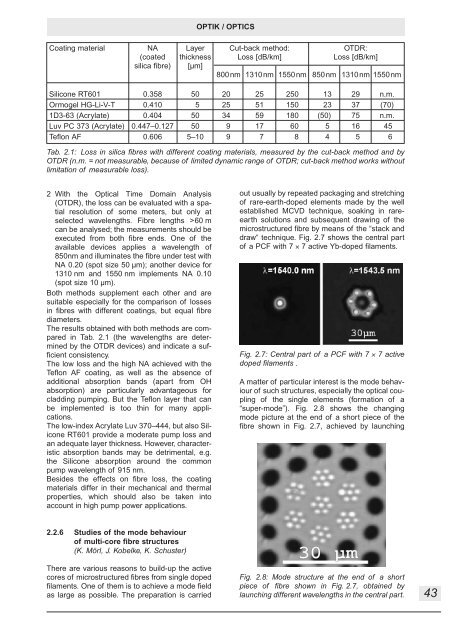

OPTIK / OPTICS<br />

Coating material NA Layer Cut-back method: OTDR:<br />

(coated thickness Loss [dB/km] Loss [dB/km]<br />

silica fibre) [µm]<br />

800nm 1310nm 1550nm 850nm 1310nm 1550nm<br />

Silicone RT601 0.358 50 20 25 250 13 29 n.m.<br />

Ormogel HG-Li-V-T 0.410 5 25 51 150 23 37 (70)<br />

1D3-63 (Acrylate) 0.404 50 34 59 180 (50) 75 n.m.<br />

Luv PC 373 (Acrylate) 0.447–0.127 50 9 17 60 5 16 45<br />

Teflon AF 0.606 5–10 9 7 8 4 5 6<br />

Tab. 2.1: Loss in silica fibres with different coating materials, measured by the cut-back method and by<br />

OTDR (n.m. = not measurable, because of limited dynamic range of OTDR; cut-back method works without<br />

limitation of measurable loss).<br />

2 With the Optical Time Domain Analysis<br />

(OTDR), the loss can be evaluated with a spatial<br />

resolution of some meters, but only at<br />

selected wavelengths. Fibre lengths >60 m<br />

can be analysed; the measurements should be<br />

executed from both fibre ends. One of the<br />

available devices applies a wavelength of<br />

850nm and illuminates the fibre under test with<br />

NA 0.20 (spot size 50 µm); another device for<br />

1310 nm and 1550 nm implements NA 0.10<br />

(spot size 10 µm).<br />

Both methods supplement each other and are<br />

suitable especially for the comparison of losses<br />

in fibres with different coatings, but equal fibre<br />

diameters.<br />

The results obtained with both methods are compared<br />

in Tab. 2.1 (the wavelengths are determined<br />

by the OTDR devices) and indicate a sufficient<br />

consistency.<br />

The low loss and the high NA achieved with the<br />

Teflon AF coating, as well as the absence of<br />

additional absorption bands (apart from OH<br />

absorption) are particularly advantageous for<br />

cladding pumping. But the Teflon layer that can<br />

be implemented is too thin for many applications.<br />

The low-index Acrylate Luv 370–444, but also Silicone<br />

RT601 provide a moderate pump loss and<br />

an adequate layer thickness. However, characteristic<br />

absorption bands may be detrimental, e.g.<br />

the Silicone absorption around the common<br />

pump wavelength of 915 nm.<br />

Besides the effects on fibre loss, the coating<br />

materials differ in their mechanical and thermal<br />

properties, which should also be taken into<br />

account in high pump power applications.<br />

2.2.6 Studies of the mode behaviour<br />

of multi-core fibre structures<br />

(K. Mörl, J. Kobelke, K. Schuster)<br />

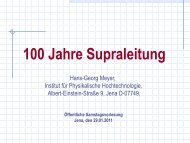

There are various reasons to build-up the active<br />

cores of microstructured fibres from single doped<br />

filaments. One of them is to achieve a mode field<br />

as large as possible. The preparation is carried<br />

out usually by repeated packaging and stretching<br />

of rare-earth-doped elements made by the well<br />

established MCVD technique, soaking in rareearth<br />

solutions and subsequent drawing of the<br />

microstructured fibre by means of the “stack and<br />

draw“ technique. Fig. 2.7 shows the central part<br />

of a PCF with 7 × 7 active Yb-doped filaments.<br />

Fig. 2.7: Central part of a PCF with 7 × 7 active<br />

doped filaments .<br />

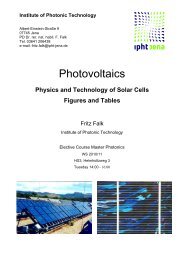

A matter of particular interest is the mode behaviour<br />

of such structures, especially the optical coupling<br />

of the single elements (formation of a<br />

“super-mode”). Fig. 2.8 shows the changing<br />

mode picture at the end of a short piece of the<br />

fibre shown in Fig. 2.7, achieved by launching<br />

Fig. 2.8: Mode structure at the end of a short<br />

piece of fibre shown in Fig. 2.7, obtained by<br />

launching different wavelengths in the central part.<br />

43