Jahresbericht 2005 - IPHT Jena

Jahresbericht 2005 - IPHT Jena

Jahresbericht 2005 - IPHT Jena

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

46<br />

comprising a semiconductor laser and an extended<br />

external cavity. On the one hand, the FGL concept<br />

for Non-Return-to-Zero (NRZ) data transmission<br />

is considered as a potential low-cost data<br />

transmitter device; on the other hand, the laser<br />

output power and emission wavelength is shown<br />

to be sensitive to packaging, laser temperature<br />

and device current (see <strong>IPHT</strong> annual report<br />

2001).<br />

FGL understanding and optimization require simulation<br />

tools, which have been developed at the<br />

<strong>IPHT</strong>. The numerical method bases on the travelling<br />

wave model for DFB (distributed feedback)<br />

semiconductor lasers. As the lasing condition of<br />

the external cavity laser depends on its own history,<br />

the applied model splits the laser into individual<br />

sections, each with its own treatment of<br />

rate equations, (Bragg) reflections and losses.<br />

The simulation tools give access to the complex<br />

output power behaviour, mode jumps and eye.<br />

Additionally it is now possible to design special<br />

laser architectures like mode-hop-free FGLs with<br />

active wavelength stabilization and wavelengthswitchable<br />

FGLs, which are based on the interaction<br />

between the external cavity with superimposed<br />

Bragg gratings and the internal cavity,<br />

which comprises the semiconductor optical<br />

amplifier section.<br />

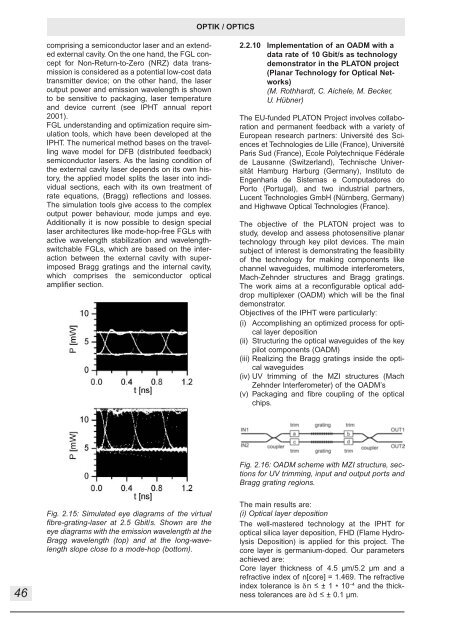

Fig. 2.15: Simulated eye diagrams of the virtual<br />

fibre-grating-laser at 2.5 Gbit/s. Shown are the<br />

eye diagrams with the emission wavelength at the<br />

Bragg wavelength (top) and at the long-wavelength<br />

slope close to a mode-hop (bottom).<br />

OPTIK / OPTICS<br />

2.2.10 Implementation of an OADM with a<br />

data rate of 10 Gbit/s as technology<br />

demonstrator in the PLATON project<br />

(Planar Technology for Optical Networks)<br />

(M. Rothhardt, C. Aichele, M. Becker,<br />

U. Hübner)<br />

The EU-funded PLATON Project involves collaboration<br />

and permanent feedback with a variety of<br />

European research partners: Université des Sciences<br />

et Technologies de Lille (France), Université<br />

Paris Sud (France), Ecole Polytechnique Fédérale<br />

de Lausanne (Switzerland), Technische Universität<br />

Hamburg Harburg (Germany), Instituto de<br />

Engenharia de Sistemas e Computadores do<br />

Porto (Portugal), and two industrial partners,<br />

Lucent Technologies GmbH (Nürnberg, Germany)<br />

and Highwave Optical Technologies (France).<br />

The objective of the PLATON project was to<br />

study, develop and assess photosensitive planar<br />

technology through key pilot devices. The main<br />

subject of interest is demonstrating the feasibility<br />

of the technology for making components like<br />

channel waveguides, multimode interferometers,<br />

Mach-Zehnder structures and Bragg gratings.<br />

The work aims at a reconfigurable optical adddrop<br />

multiplexer (OADM) which will be the final<br />

demonstrator.<br />

Objectives of the <strong>IPHT</strong> were particularly:<br />

(i) Accomplishing an optimized process for optical<br />

layer deposition<br />

(ii) Structuring the optical waveguides of the key<br />

pilot components (OADM)<br />

(iii) Realizing the Bragg gratings inside the optical<br />

waveguides<br />

(iv) UV trimming of the MZI structures (Mach<br />

Zehnder Interferometer) of the OADM’s<br />

(v) Packaging and fibre coupling of the optical<br />

chips.<br />

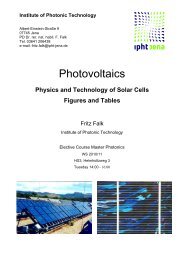

Fig. 2.16: OADM scheme with MZI structure, sections<br />

for UV trimming, input and output ports and<br />

Bragg grating regions.<br />

The main results are:<br />

(i) Optical layer deposition<br />

The well-mastered technology at the <strong>IPHT</strong> for<br />

optical silica layer deposition, FHD (Flame Hydrolysis<br />

Deposition) is applied for this project. The<br />

core layer is germanium-doped. Our parameters<br />

achieved are:<br />

Core layer thickness of 4.5 µm/5.2 µm and a<br />

refractive index of n[core] = 1.469. The refractive<br />

index tolerance is δn