MC Series Gas-Fired Circulating Heater - Heat Transfer Products, Inc

MC Series Gas-Fired Circulating Heater - Heat Transfer Products, Inc

MC Series Gas-Fired Circulating Heater - Heat Transfer Products, Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

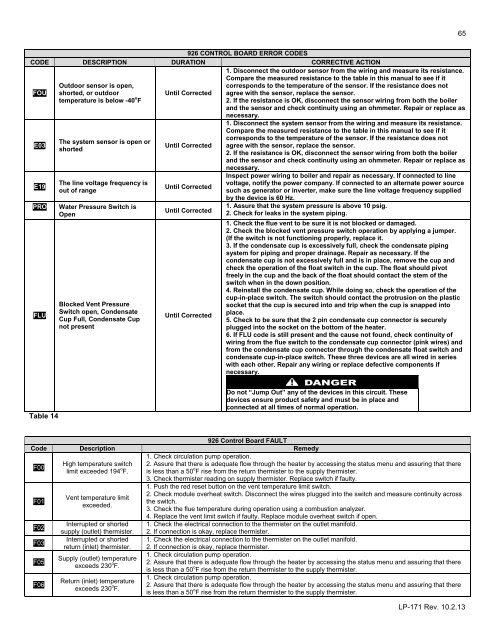

65<br />

926 CONTROL BOARD ERROR CODES<br />

CODE DESCRIPTION DURATION CORRECTIVE ACTION<br />

FOU<br />

E03<br />

E19<br />

PRO<br />

FLU<br />

Outdoor sensor is open,<br />

shorted, or outdoor<br />

temperature is below -40 o F<br />

The system sensor is open or<br />

shorted<br />

The line voltage frequency is<br />

out of range<br />

Water Pressure Switch is<br />

Open<br />

Blocked Vent Pressure<br />

Switch open, Condensate<br />

Cup Full, Condensate Cup<br />

not present<br />

Until Corrected<br />

Until Corrected<br />

Until Corrected<br />

Until Corrected<br />

Until Corrected<br />

1. Disconnect the outdoor sensor from the wiring and measure its resistance.<br />

Compare the measured resistance to the table in this manual to see if it<br />

corresponds to the temperature of the sensor. If the resistance does not<br />

agree with the sensor, replace the sensor.<br />

2. If the resistance is OK, disconnect the sensor wiring from both the boiler<br />

and the sensor and check continuity using an ohmmeter. Repair or replace as<br />

necessary.<br />

1. Disconnect the system sensor from the wiring and measure its resistance.<br />

Compare the measured resistance to the table in this manual to see if it<br />

corresponds to the temperature of the sensor. If the resistance does not<br />

agree with the sensor, replace the sensor.<br />

2. If the resistance is OK, disconnect the sensor wiring from both the boiler<br />

and the sensor and check continuity using an ohmmeter. Repair or replace as<br />

necessary.<br />

Inspect power wiring to boiler and repair as necessary. If connected to line<br />

voltage, notify the power company. If connected to an alternate power source<br />

such as generator or inverter, make sure the line voltage frequency supplied<br />

by the device is 60 Hz.<br />

1. Assure that the system pressure is above 10 psig.<br />

2. Check for leaks in the system piping.<br />

1. Check the flue vent to be sure it is not blocked or damaged.<br />

2. Check the blocked vent pressure switch operation by applying a jumper.<br />

(If the switch is not functioning properly, replace it.<br />

3. If the condensate cup is excessively full, check the condensate piping<br />

system for piping and proper drainage. Repair as necessary. If the<br />

condensate cup is not excessively full and is in place, remove the cup and<br />

check the operation of the float switch in the cup. The float should pivot<br />

freely in the cup and the back of the float should contact the stem of the<br />

switch when in the down position.<br />

4. Reinstall the condensate cup. While doing so, check the operation of the<br />

cup-in-place switch. The switch should contact the protrusion on the plastic<br />

socket that the cup is secured into and trip when the cup is snapped into<br />

place.<br />

5. Check to be sure that the 2 pin condensate cup connector is securely<br />

plugged into the socket on the bottom of the heater.<br />

6. If FLU code is still present and the cause not found, check continuity of<br />

wiring from the flue switch to the condensate cup connector (pink wires) and<br />

from the condensate cup connector through the condensate float switch and<br />

condensate cup-in-place switch. These three devices are all wired in series<br />

with each other. Repair any wiring or replace defective components if<br />

necessary.<br />

Table 14<br />

Do not “Jump Out” any of the devices in this circuit. These<br />

devices ensure product safety and must be in place and<br />

connected at all times of normal operation.<br />

926 Control Board FAULT<br />

Code Description Remedy<br />

F00<br />

F01<br />

F02<br />

F03<br />

F05<br />

F06<br />

High temperature switch<br />

limit exceeded 194 o F.<br />

Vent temperature limit<br />

exceeded.<br />

Interrupted or shorted<br />

supply (outlet) thermister.<br />

Interrupted or shorted<br />

return (inlet) thermister.<br />

Supply (outlet) temperature<br />

exceeds 230 o F.<br />

Return (inlet) temperature<br />

exceeds 230 o F.<br />

1. Check circulation pump operation.<br />

2. Assure that there is adequate flow through the heater by accessing the status menu and assuring that there<br />

is less than a 50 o F rise from the return thermister to the supply thermister.<br />

3. Check thermister reading on supply thermister. Replace switch if faulty.<br />

1. Push the red reset button on the vent temperature limit switch.<br />

2. Check module overheat switch. Disconnect the wires plugged into the switch and measure continuity across<br />

the switch.<br />

3. Check the flue temperature during operation using a combustion analyzer.<br />

4. Replace the vent limit switch if faulty. Replace module overheat switch if open.<br />

1. Check the electrical connection to the thermister on the outlet manifold.<br />

2. If connection is okay, replace thermister.<br />

1. Check the electrical connection to the thermister on the outlet manifold.<br />

2. If connection is okay, replace thermister.<br />

1. Check circulation pump operation.<br />

2. Assure that there is adequate flow through the heater by accessing the status menu and assuring that there<br />

is less than a 50 o F rise from the return thermister to the supply thermister.<br />

1. Check circulation pump operation.<br />

2. Assure that there is adequate flow through the heater by accessing the status menu and assuring that there<br />

is less than a 50 o F rise from the return thermister to the supply thermister.<br />

LP-171 Rev. 10.2.13