MC Series Gas-Fired Circulating Heater - Heat Transfer Products, Inc

MC Series Gas-Fired Circulating Heater - Heat Transfer Products, Inc

MC Series Gas-Fired Circulating Heater - Heat Transfer Products, Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

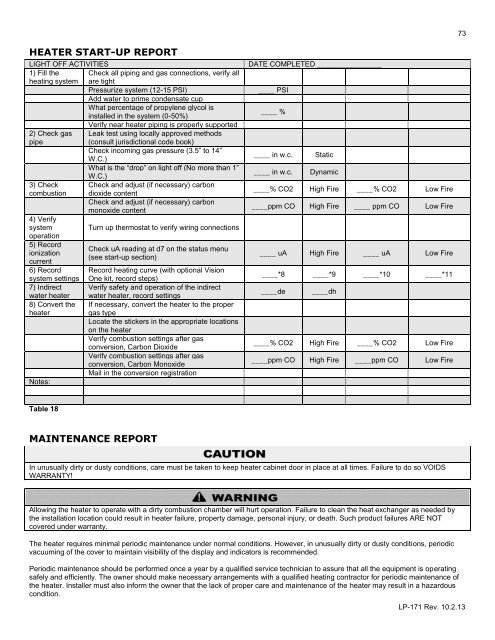

73<br />

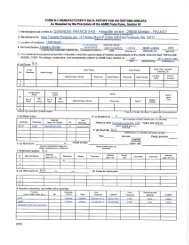

HEATER START-UP REPORT<br />

LIGHT OFF ACTIVITIES<br />

1) Fill the Check all piping and gas connections, verify all<br />

heating system are tight<br />

Pressurize system (12-15 PSI)<br />

Add water to prime condensate cup<br />

What percentage of propylene glycol is<br />

installed in the system (0-50%)<br />

2) Check gas<br />

pipe<br />

3) Check<br />

combustion<br />

4) Verify<br />

system<br />

operation<br />

5) Record<br />

ionization<br />

current<br />

6) Record<br />

system settings<br />

7) Indirect<br />

water heater<br />

8) Convert the<br />

heater<br />

Notes:<br />

Verify near heater piping is properly supported<br />

Leak test using locally approved methods<br />

(consult jurisdictional code book)<br />

Check incoming gas pressure (3.5” to 14”<br />

W.C.)<br />

What is the “drop” on light off (No more than 1”<br />

W.C.)<br />

Check and adjust (if necessary) carbon<br />

dioxide content<br />

Check and adjust (if necessary) carbon<br />

monoxide content<br />

Turn up thermostat to verify wiring connections<br />

Check uA reading at d7 on the status menu<br />

(see start-up section)<br />

Record heating curve (with optional Vision<br />

One kit, record steps)<br />

Verify safety and operation of the indirect<br />

water heater, record settings<br />

If necessary, convert the heater to the proper<br />

gas type<br />

Locate the stickers in the appropriate locations<br />

on the heater<br />

Verify combustion settings after gas<br />

conversion, Carbon Dioxide<br />

Verify combustion settings after gas<br />

conversion, Carbon Monoxide<br />

Mail in the conversion registration<br />

DATE COMPLETED ________________<br />

____ PSI<br />

____ %<br />

____ in w.c. Static<br />

____ in w.c. Dynamic<br />

____% CO2 High Fire ____% CO2 Low Fire<br />

____ppm CO High Fire ____ ppm CO Low Fire<br />

____ uA High Fire ____ uA Low Fire<br />

____*8 ____*9 ____*10 ____*11<br />

____de ____dh<br />

____% CO2 High Fire ____% CO2 Low Fire<br />

____ppm CO High Fire ____ppm CO Low Fire<br />

Table 18<br />

MAINTENANCE REPORT<br />

In unusually dirty or dusty conditions, care must be taken to keep heater cabinet door in place at all times. Failure to do so VOIDS<br />

WARRANTY!<br />

Allowing the heater to operate with a dirty combustion chamber will hurt operation. Failure to clean the heat exchanger as needed by<br />

the installation location could result in heater failure, property damage, personal injury, or death. Such product failures ARE NOT<br />

covered under warranty.<br />

The heater requires minimal periodic maintenance under normal conditions. However, in unusually dirty or dusty conditions, periodic<br />

vacuuming of the cover to maintain visibility of the display and indicators is recommended.<br />

Periodic maintenance should be performed once a year by a qualified service technician to assure that all the equipment is operating<br />

safely and efficiently. The owner should make necessary arrangements with a qualified heating contractor for periodic maintenance of<br />

the heater. Installer must also inform the owner that the lack of proper care and maintenance of the heater may result in a hazardous<br />

condition.<br />

LP-171 Rev. 10.2.13