Discover New Applications For Low-Cost Solutions Discover ... - Xilinx

Discover New Applications For Low-Cost Solutions Discover ... - Xilinx

Discover New Applications For Low-Cost Solutions Discover ... - Xilinx

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Take the Titanium Solution<br />

<strong>Xilinx</strong> Titanium Technical Service engineers coach clients through design issues.<br />

by Vikram Pasham<br />

Design Engineer, <strong>Xilinx</strong> Design Services<br />

<strong>Xilinx</strong>, Inc.<br />

vikram.pasham@xilinx.com<br />

Need to enhance your design productivity?<br />

Decrease your design costs? Accelerate time<br />

to market? With the complexities and possibilities<br />

of today’s designs, it’s easy to get<br />

sidetracked from your main goals.<br />

<strong>Xilinx</strong> Titanium Technical Service provides<br />

on-site or off-site support for clients<br />

on a contract basis. Titanium application<br />

engineers are adept at ensuring that you<br />

start and finish your designs the right way.<br />

Our engineers provide design methodology<br />

coaching to make sure you take the most<br />

efficient approach. And our engineers’ skill<br />

at tracing debug issues back to the design is<br />

one of our most powerful services. Here’s<br />

an example from one of our clients.<br />

Customer Challenges<br />

During the development of a high-definition<br />

television (HDTV) video application, the<br />

engineering team of our client company<br />

(which prefers to remain anonymous for<br />

competitive reasons) had developed proprietary<br />

DSP algorithms for uniform video<br />

correction. These were implemented on a<br />

custom ASIC developed by a third party,<br />

which had several silicon bugs.<br />

Fearing that the bugs would cost them<br />

the chance to be first to market with their<br />

technology, the engineers ported part of the<br />

ASIC’s functionality to a <strong>Xilinx</strong> FPGA. Yet<br />

they still noticed that prototypes, when<br />

tested in the lab, had power-up and image<br />

distortion issues. Thus, they decided to<br />

bring in a dedicated <strong>Xilinx</strong> Titanium<br />

Technical Service application engineer.<br />

At the time, the customer’s main<br />

challenges were:<br />

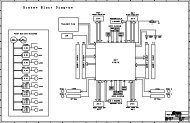

• A densely packed design using<br />

99% slices, 70% block RAMs,<br />

and multipliers in a Virtex-II<br />

device. They wanted to add additional<br />

features into the FPGA, but did not<br />

have the budget to use a larger one.<br />

• They couldn’t meet timing in their<br />

Virtex-II –4 speed grade part and were<br />

using –5 speed grade. This increased<br />

their bill of materials.<br />

• This design had to support six different<br />

pin configurations for different RGB<br />

connectors on different boards.<br />

• The prototypes were behaving<br />

inconsistently on power-up and<br />

exhibiting image distortion.<br />

The Titanium Solution<br />

Over the course of one week, a <strong>Xilinx</strong><br />

Titanium engineer gave the client’s engineering<br />

team a crash course on FPGA<br />

design techniques and constraints. He suggested<br />

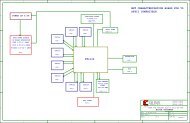

replacing the existing design’s clocking<br />

structure with Virtex-II digital clock<br />

managers (DCMs) for multiple clock generations.<br />

After learning about the features of<br />

DCMs, the engineering team discovered<br />

they could use DCM status bits to determine<br />

if the digital video interface (DVI)<br />

clock was disconnected. Based on this discovery,<br />

the team designed a robust recovery<br />

mechanism. This solved the power-up and<br />

image distortion problems.<br />

The existing design was already using all<br />

of the resources of the FPGA, yet there were<br />

further requirements to add functionality.<br />

The Titanium engineer identified portions<br />

of the design that weren’t suited for FPGA<br />

architecture. He recommended other changes<br />

for optimal efficiency, while still preserving<br />

design functionality. Knowing that Virtex-II<br />

silicon can easily meet 60 MHz DVI clock<br />

rates, he suggested using tight packing<br />

options in map tools, and using the multipass<br />

place-and-route and floorplanning features<br />

in <strong>Xilinx</strong> ISE tools. This freed up enough<br />

resources for the engineers to add the additional<br />

features in the FPGA.<br />

To meet timing in the Virtex-II –4 speed<br />

grade part for the six different pin configurations,<br />

the Titanium engineer placed timing<br />

constraints to cover all the clocks, cross clock<br />

domain paths, and multicycle paths.<br />

Together, they put together working prototypes<br />

in the lab supporting the six different<br />

pin configurations.<br />

After these adjustments to the design,<br />

the company is now able to use a lowerspeed<br />

grade part, reducing their system cost.<br />

They are on schedule to meet their time-tomarket<br />

goals.<br />

Conclusion<br />

A Titanium Technical Service application<br />

engineer can work at <strong>Xilinx</strong>, on-site, or a<br />

mix of both. This flexibility allows the<br />

engineers to fully understand the needs and<br />

requirements of our clients, as well as leverage<br />

<strong>Xilinx</strong> factory resources to resolve problems<br />

and accelerate production.<br />

<strong>For</strong> more information about Titanium<br />

Technical Services, please call 800-888-<br />

FPGA (3742) or visit http://support.<br />

xilinx.com/support/services/titanium.htm.<br />

Fall 2003 Xcell Journal 71