Master Thesis - Fachbereich Informatik

Master Thesis - Fachbereich Informatik

Master Thesis - Fachbereich Informatik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.3. EXPERIMENTAL RESULTS 123<br />

Length [mm]<br />

50.4<br />

50.2<br />

50<br />

49.8<br />

49.6<br />

Measurements<br />

Mean<br />

0 20 40 60 80 100<br />

N<br />

(a)<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

Measurement distribution<br />

0<br />

49.4 49.6 49.8 50<br />

Length [mm]<br />

50.2 50.4 50.6<br />

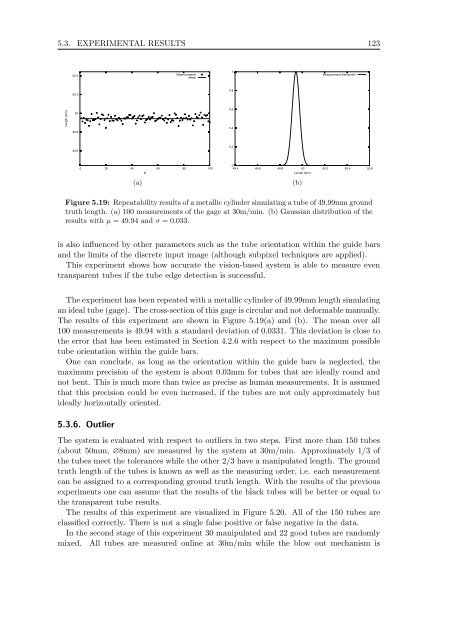

Figure 5.19: Repeatability results of a metallic cylinder simulating a tube of 49.99mm ground<br />

truth length. (a) 100 measurements of the gage at 30m/min. (b) Gaussian distribution of the<br />

results with µ =49.94 and σ =0.033.<br />

is also influenced by other parameters such as the tube orientation within the guide bars<br />

and the limits of the discrete input image (although subpixel techniques are applied).<br />

This experiment shows how accurate the vision-based system is able to measure even<br />

transparent tubes if the tube edge detection is successful.<br />

The experiment has been repeated with a metallic cylinder of 49.99mm length simulating<br />

an ideal tube (gage). The cross-section of this gage is circular and not deformable manually.<br />

The results of this experiment are shown in Figure 5.19(a) and (b). The mean over all<br />

100 measurements is 49.94 with a standard deviation of 0.0331. This deviation is close to<br />

the error that has been estimated in Section 4.2.6 with respect to the maximum possible<br />

tube orientation within the guide bars.<br />

One can conclude, as long as the orientation within the guide bars is neglected, the<br />

maximum precision of the system is about 0.03mm for tubes that are ideally round and<br />

not bent. This is much more than twice as precise as human measurements. It is assumed<br />

that this precision could be even increased, if the tubes are not only approximately but<br />

ideally horizontally oriented.<br />

5.3.6. Outlier<br />

The system is evaluated with respect to outliers in two steps. First more than 150 tubes<br />

(about 50mm, ∅8mm) are measured by the system at 30m/min. Approximately 1/3 of<br />

thetubesmeetthetoleranceswhiletheother2/3 have a manipulated length. The ground<br />

truth length of the tubes is known as well as the measuring order, i.e. each measurement<br />

can be assigned to a corresponding ground truth length. With the results of the previous<br />

experiments one can assume that the results of the black tubes will be better or equal to<br />

the transparent tube results.<br />

The results of this experiment are visualized in Figure 5.20. All of the 150 tubes are<br />

classified correctly. There is not a single false positive or false negative in the data.<br />

In the second stage of this experiment 30 manipulated and 22 good tubes are randomly<br />

mixed. All tubes are measured online at 30m/min while the blow out mechanism is<br />

(b)