Master Thesis - Fachbereich Informatik

Master Thesis - Fachbereich Informatik

Master Thesis - Fachbereich Informatik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

48 CHAPTER 3. HARDWARE CONFIGURATION<br />

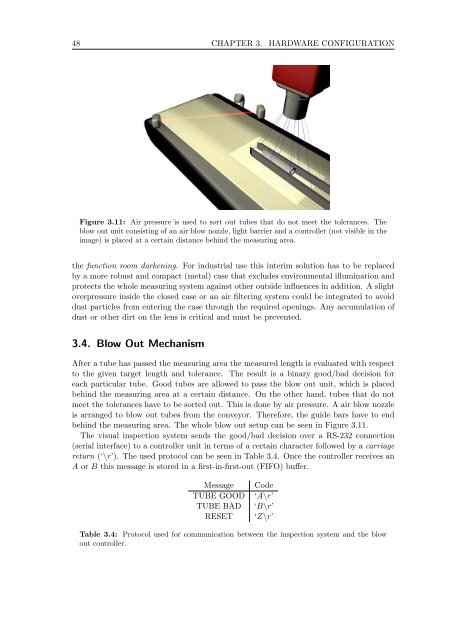

Figure 3.11: Air pressure is used to sort out tubes that do not meet the tolerances. The<br />

blow out unit consisting of an air blow nozzle, light barrier and a controller (not visible in the<br />

image) is placed at a certain distance behind the measuring area.<br />

the function room darkening. For industrial use this interim solution has to be replaced<br />

by a more robust and compact (metal) case that excludes environmental illumination and<br />

protects the whole measuring system against other outside influences in addition. A slight<br />

overpressure inside the closed case or an air filtering system could be integrated to avoid<br />

dust particles from entering the case through the required openings. Any accumulation of<br />

dust or other dirt on the lens is critical and must be prevented.<br />

3.4. Blow Out Mechanism<br />

After a tube has passed the measuring area the measured length is evaluated with respect<br />

to the given target length and tolerance. The result is a binary good/bad decision for<br />

each particular tube. Good tubes are allowed to pass the blow out unit, which is placed<br />

behind the measuring area at a certain distance. On the other hand, tubes that do not<br />

meetthetoleranceshavetobesortedout. Thisisdonebyairpressure. Aairblownozzle<br />

is arranged to blow out tubes from the conveyor. Therefore, the guide bars have to end<br />

behind the measuring area. The whole blow out setup can be seen in Figure 3.11.<br />

The visual inspection system sends the good/bad decision over a RS-232 connection<br />

(serial interface) to a controller unit in terms of a certain character followed by a carriage<br />

return (‘\r’). The used protocol can be seen in Table 3.4. Once the controller receives an<br />

A or B this message is stored in a first-in-first-out (FIFO) buffer.<br />

Message Code<br />

TUBE GOOD ‘A\r’<br />

TUBE BAD ‘B\r’<br />

RESET ‘Z\r’<br />

Table 3.4: Protocol used for communication between the inspection system and the blow<br />

out controller.