Master Thesis - Fachbereich Informatik

Master Thesis - Fachbereich Informatik

Master Thesis - Fachbereich Informatik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

124 CHAPTER 5. RESULTS AND EVALUATION<br />

52<br />

51.5<br />

51<br />

50.5<br />

50<br />

49.5<br />

49<br />

48.5<br />

48<br />

upper tolerance<br />

lower tolerance<br />

resulting mean length<br />

ground truth<br />

0 20 40 60 80 100 120 140<br />

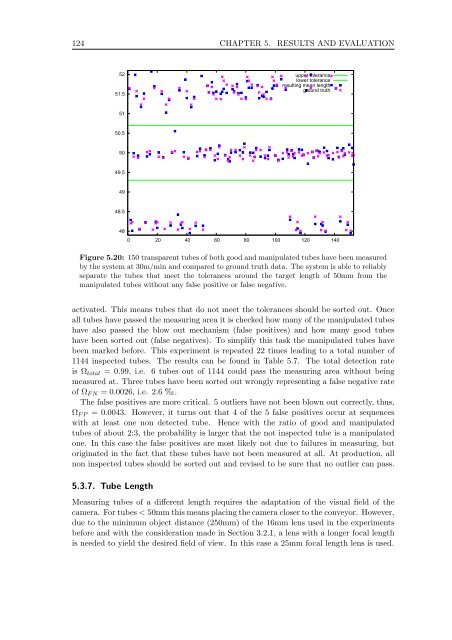

Figure 5.20: 150 transparent tubes of both good and manipulated tubes have been measured<br />

by the system at 30m/min and compared to ground truth data. The system is able to reliably<br />

separate the tubes that meet the tolerances around the target length of 50mm from the<br />

manipulated tubes without any false positive or false negative.<br />

activated. This means tubes that do not meet the tolerances should be sorted out. Once<br />

all tubes have passed the measuring area it is checked how many of the manipulated tubes<br />

have also passed the blow out mechanism (false positives) and how many good tubes<br />

have been sorted out (false negatives). To simplify this task the manipulated tubes have<br />

been marked before. This experiment is repeated 22 times leading to a total number of<br />

1144 inspected tubes. The results can be found in Table 5.7. The total detection rate<br />

is Ωtotal =0.99, i.e. 6 tubes out of 1144 could pass the measuring area without being<br />

measured at. Three tubes have been sorted out wrongly representing a false negative rate<br />

of ΩFN =0.0026, i.e. 2.6 .<br />

The false positives are more critical. 5 outliers have not been blown out correctly, thus,<br />

ΩFP =0.0043. However, it turns out that 4 of the 5 false positives occur at sequences<br />

with at least one non detected tube. Hence with the ratio of good and manipulated<br />

tubes of about 2:3, the probability is larger that the not inspected tube is a manipulated<br />

one. In this case the false positives are most likely not due to failures in measuring, but<br />

originated in the fact that these tubes have not been measured at all. At production, all<br />

non inspected tubes should be sorted out and revised to be sure that no outlier can pass.<br />

5.3.7. Tube Length<br />

Measuring tubes of a different length requires the adaptation of the visual field of the<br />

camera. For tubes < 50mm this means placing the camera closer to the conveyor. However,<br />

due to the minimum object distance (250mm) of the 16mm lens used in the experiments<br />

before and with the consideration made in Section 3.2.1, a lens with a longer focal length<br />

is needed to yield the desired field of view. In this case a 25mm focal length lens is used.