Installation Manual - Model 5 - Tundra Process Solutions Ltd.

Installation Manual - Model 5 - Tundra Process Solutions Ltd.

Installation Manual - Model 5 - Tundra Process Solutions Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

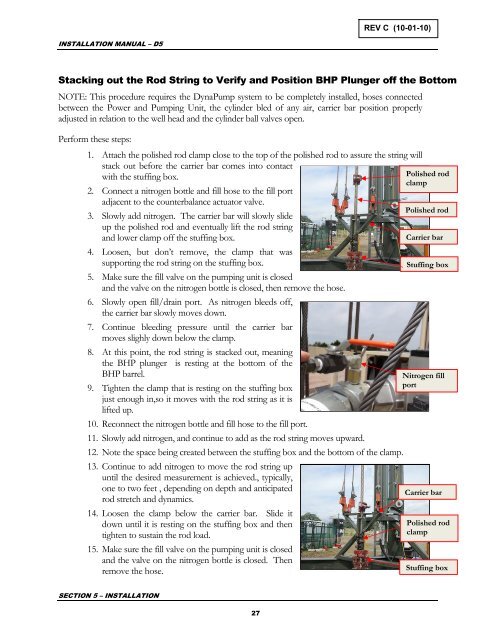

REV C (10-01-10)INSTALLATION MANUAL – D5Stacking out the Rod String to Verify and Position BHP Plunger off the BottomNOTE: This procedure requires the DynaPump system to be completely installed, hoses connectedbetween the Power and Pumping Unit, the cylinder bled of any air, carrier bar position properlyadjusted in relation to the well head and the cylinder ball valves open.Perform these steps:1. Attach the polished rod clamp close to the top of the polished rod to assure the string willstack out before the carrier bar comes into contactwith the stuffing box.2. Connect a nitrogen bottle and fill hose to the fill portadjacent to the counterbalance actuator valve.3. Slowly add nitrogen. The carrier bar will slowly slideup the polished rod and eventually lift the rod stringand lower clamp off the stuffing box.4. Loosen, but don’t remove, the clamp that wassupporting the rod string on the stuffing box.5. Make sure the fill valve on the pumping unit is closedand the valve on the nitrogen bottle is closed, then remove the hose.6. Slowly open fill/drain port. As nitrogen bleeds off,the carrier bar slowly moves down.7. Continue bleeding pressure until the carrier barmoves slighly down below the clamp.8. At this point, the rod string is stacked out, meaningthe BHP plunger is resting at the bottom of theBHP barrel.9. Tighten the clamp that is resting on the stuffing boxjust enough in,so it moves with the rod string as it islifted up.10. Reconnect the nitrogen bottle and fill hose to the fill port.11. Slowly add nitrogen, and continue to add as the rod string moves upward.12. Note the space being created between the stuffing box and the bottom of the clamp.13. Continue to add nitrogen to move the rod string upuntil the desired measurement is achieved., typically,one to two feet , depending on depth and anticipatedCarrier barrod stretch and dynamics.14. Loosen the clamp below the carrier bar. Slide itdown until it is resting on the stuffing box and thentighten to sustain the rod load.15. Make sure the fill valve on the pumping unit is closedand the valve on the nitrogen bottle is closed. Thenremove the hose.Polished rodclampPolished rodCarrier barStuffing boxNitrogen fillportPolished rodclampStuffing boxSECTION 5 – INSTALLATION27