- Page 3 and 4:

DECLARATION“I certify that this w

- Page 6 and 7:

taste masking effect of the process

- Page 8 and 9:

CHAPTER 2: DISSOLUTION ENHANCEMENT

- Page 10 and 11:

3.2 Powder and ODT characterization

- Page 12 and 13:

3.7 In vitro drug release profiles

- Page 15:

3.1 Solubility parameters and extru

- Page 18 and 19:

polymers.7.2 DSC findings of all AP

- Page 20 and 21:

2.4b Diffractograms of FMT formulat

- Page 22 and 23:

4.3 Schematic representation of the

- Page 24 and 25:

55 exrudates (b) DPD/L100-55 PM (c)

- Page 26 and 27:

8.5d A plot of the logarithm of HCS

- Page 28 and 29:

L100Eudragit L100L100-55 Eudragit L

- Page 30 and 31:

Maniruzzaman M, Rai D, Boateng JS.

- Page 32 and 33:

Maniruzzaman M, Boateng JS, Bonnefi

- Page 34 and 35:

CHAPTER 1: INTRODUCTION1.0 Backgrou

- Page 36 and 37:

Table 1.1: HME and other convention

- Page 38 and 39:

homogenize but also compress the ex

- Page 40 and 41:

properties of polymers and excipien

- Page 42 and 43:

particles‘ wettability [46] . A v

- Page 44 and 45:

Table 1.2: Different hot-melt extru

- Page 46 and 47:

1.8 Aims and objectivesThe purpose

- Page 48 and 49:

29. Zheng X, Yang R, Tang X and Zhe

- Page 50 and 51:

56. International Conference on Har

- Page 52 and 53:

CHAPTER 2: DISSOLUTION ENHANCEMENT

- Page 54 and 55:

Fdid ,Vi F2pip , p( Ehi/ ViVi )i =

- Page 56 and 57:

used. Each sample was scanned from

- Page 58 and 59:

Furthermore, by means of thermodyna

- Page 60 and 61:

3.2 Particle size morphology and pa

- Page 62 and 63:

Fig. 2.4a: Diffractograms of INM fo

- Page 64 and 65:

However, the DSC thermograms of the

- Page 66 and 67:

Fig. 2.5b: DSC thermograms of INM a

- Page 68 and 69:

Fig. 2.5e: DSC thermograms of FMT a

- Page 70 and 71:

Nevertheless, more than 80% FMT was

- Page 72 and 73:

6. Caron V, Tajber L, Corrigan OI,

- Page 74 and 75:

CHAPTER 3: DEVELOPMENT AND EVALUATI

- Page 76 and 77:

2.2 Hot-Melt extrusionHot-melt extr

- Page 78 and 79:

Committee of the University of Gree

- Page 80 and 81:

The PM of formulation II (40% IBU)

- Page 82 and 83:

Fig. 3.3: DSC thermograms of pure I

- Page 84 and 85:

As a general rule, the powder compr

- Page 86 and 87:

Fig. 3.4: Schematic diagram of ODT

- Page 88 and 89:

Fig. 3.5: Schematic diagram of ODTs

- Page 90 and 91:

Fig. 3.7: Schematic diagram of ODTs

- Page 92 and 93:

F2 0 0.5 0 1 0 1F6 0 0.5 0 1 0 2F7

- Page 94 and 95:

6. M.F. Al-Omran, S.A. Al-Suwayeh,

- Page 96 and 97:

30. L. Saerens, L. Dierickx, B. Len

- Page 98 and 99:

leading to significant variations w

- Page 100 and 101:

2.6. In vitro drug release studiesI

- Page 102 and 103:

v2d 2p(4.1)Table 4.1: Calculated so

- Page 104 and 105:

The observed melting peaks are shif

- Page 106 and 107:

Fig. 4.2a: Powder XRPD patterns of

- Page 108 and 109:

Interestingly, no difference was ob

- Page 110 and 111:

7 Astree sensors Taste masking effi

- Page 112 and 113:

The in vitro e-tongue evaluation wa

- Page 114 and 115:

3. K. Woertz, C. Tissen, P. Kleineb

- Page 116 and 117:

25. B.C. Hancock, P. York, R.C. Row

- Page 118 and 119:

CHAPTER 5: AN IN VIVO AND IN VITRO

- Page 120 and 121:

(dispersion forces and polarization

- Page 122 and 123:

Table 5.1: Sample preparation for t

- Page 124 and 125:

Table 5.2: Solubility parameters ca

- Page 126 and 127:

Physical mixtures (PM) and extruded

- Page 128 and 129:

Fig. 5.2c: Thermograms of CTZ and V

- Page 130 and 131:

masking effect for active concentra

- Page 132 and 133:

Fig. 5.5b: Distance and discriminat

- Page 134 and 135:

Table 5.4: Mean standard deviation

- Page 136 and 137: Fig. 5.6b: Release profiles of VRP

- Page 138 and 139: 17. Woertz K,Tissen C, Kleinebudde

- Page 140 and 141: scale or lower. XPS is more accurat

- Page 142 and 143: patterns were identified after ener

- Page 144 and 145: 3.3 Differential scanning calorimet

- Page 146 and 147: Fig. 6.3a: Diffractograms of PRP fo

- Page 148 and 149: good agreement with the anticipated

- Page 150 and 151: Since L100 contained higher proport

- Page 152 and 153: at ~533.01 eV is the combination of

- Page 154 and 155: Finally, the XPS analysis confirmed

- Page 156 and 157: Fig. 6.6b: 1 H NMR spectra of all P

- Page 158 and 159: 6) Bonferoni, M.C.; Rossi, S.; Ferr

- Page 160 and 161: 26) Vandencasteele, N.; Reniers, F.

- Page 162 and 163: Gibbs free energy change before and

- Page 164 and 165: 2.5 Hot-melt extrusion (HME) proces

- Page 166 and 167: 2.11 X-ray photoelectron spectrosco

- Page 168 and 169: Table 7.2: DSC findings of all APIs

- Page 170 and 171: 3.4 In vivo and in vitro taste mask

- Page 172 and 173: Fig. 7.3c: Normalised DI (%) of all

- Page 174 and 175: Table 7.4: Binding energy calculati

- Page 176 and 177: PRP/ polymers extruded in compariso

- Page 178 and 179: atom as NH + 4 . This observed N 1s

- Page 180 and 181: 8.0 ConclusionsThe presence of inte

- Page 182 and 183: 20. Davies MC, Wilding IR, Short RD

- Page 184 and 185: CHAPTER 8: SUSTAINED RELEASE HYDROC

- Page 188 and 189: medium pH was maintained as 1.2 by

- Page 190 and 191: Fig. 8.1: SEM images of [(a), (b)]

- Page 192 and 193: Fig. 8.2b: DSC transitions of HCS/E

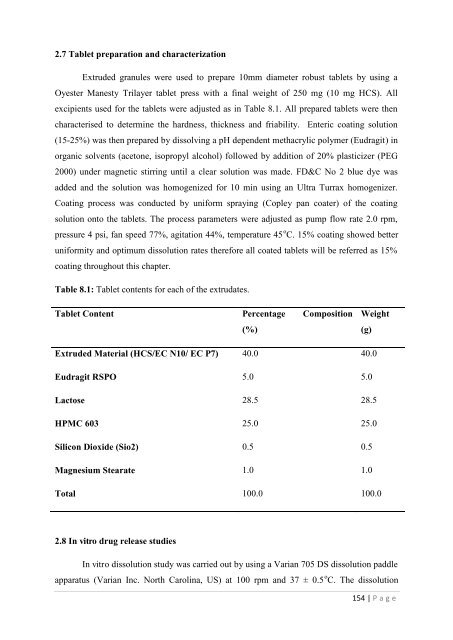

- Page 194 and 195: in the range of 10-12 kP. However,

- Page 196 and 197: ate and time on the basis of Eq. (8

- Page 198 and 199: Fig. 8.5c: A plot of the cubic root

- Page 200 and 201: when n > 0.89. From the results of

- Page 202 and 203: 14. Lam PL, Lee KKH,Wong RSM, Cheng

- Page 204 and 205: Furthermore, HME has successfully b

- Page 206 and 207: Supp. Fig. 2: XPS O 1s peaks for PR

- Page 208 and 209: Supp. Fig. 4: O 1s BE peaks for L10

- Page 210 and 211: 8.2 s 6.2 s 3.8 s 1.8 s 200 msS

- Page 212 and 213: 12.2 s 9.0 s 6.2 s 3.8 s 1.8 s

- Page 214 and 215: Supplementary table 1: Solubility p

- Page 216 and 217: N = 55000/ 219.2 = 250.912Density:

- Page 218 and 219: (4) Eudragit L100, N = (125000/202