Development of hot-melt extrusion as a novel technique for the ...

Development of hot-melt extrusion as a novel technique for the ...

Development of hot-melt extrusion as a novel technique for the ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

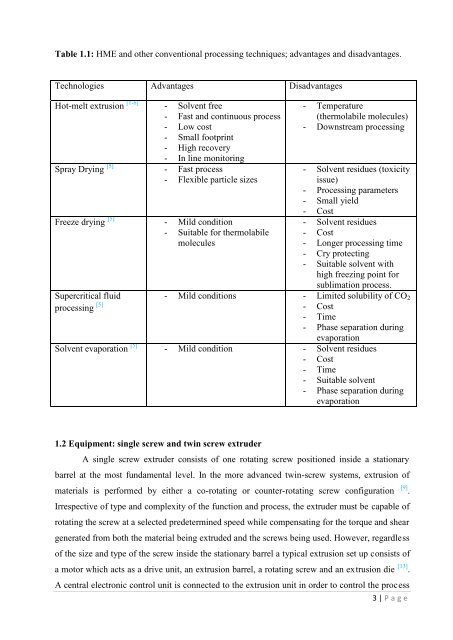

Table 1.1: HME and o<strong>the</strong>r conventional processing <strong>technique</strong>s; advantages and disadvantages.Technologies Advantages DisadvantagesHot-<strong>melt</strong> <strong>extrusion</strong> [1-6] - Solvent free- F<strong>as</strong>t and continuous process- Low cost- Small footprint- High recovery- In line monitoringSpray Drying [5] - F<strong>as</strong>t process- Flexible particle sizesFreeze drying [5] - Mild condition- Suitable <strong>for</strong> <strong>the</strong>rmolabilemolecules- Temperature(<strong>the</strong>rmolabile molecules)- Downstream processing- Solvent residues (toxicityissue)- Processing parameters- Small yield- Cost- Solvent residues- Cost- Longer processing time- Cry protecting- Suitable solvent withhigh freezing point <strong>for</strong>sublimation process.Supercritical fluid - Mild conditions - Limited solubility <strong>of</strong> CO 2processing [5] - Cost- Time- Ph<strong>as</strong>e separation duringevaporationSolvent evaporation [5] - Mild condition - Solvent residues- Cost- Time- Suitable solvent- Ph<strong>as</strong>e separation duringevaporation1.2 Equipment: single screw and twin screw extruderA single screw extruder consists <strong>of</strong> one rotating screw positioned inside a stationarybarrel at <strong>the</strong> most fundamental level. In <strong>the</strong> more advanced twin-screw systems, <strong>extrusion</strong> <strong>of</strong>materials is per<strong>for</strong>med by ei<strong>the</strong>r a co-rotating or counter-rotating screw configuration [9] .Irrespective <strong>of</strong> type and complexity <strong>of</strong> <strong>the</strong> function and process, <strong>the</strong> extruder must be capable <strong>of</strong>rotating <strong>the</strong> screw at a selected predetermined speed while compensating <strong>for</strong> <strong>the</strong> torque and sheargenerated from both <strong>the</strong> material being extruded and <strong>the</strong> screws being used. However, regardless<strong>of</strong> <strong>the</strong> size and type <strong>of</strong> <strong>the</strong> screw inside <strong>the</strong> stationary barrel a typical <strong>extrusion</strong> set up consists <strong>of</strong>a motor which acts <strong>as</strong> a drive unit, an <strong>extrusion</strong> barrel, a rotating screw and an <strong>extrusion</strong> die [13] .A central electronic control unit is connected to <strong>the</strong> <strong>extrusion</strong> unit in order to control <strong>the</strong> process3 | P a g e