Neftegaz.RU #3-17 ENG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Neftegaz</strong>.<strong>RU</strong><br />

# 3/20<strong>17</strong><br />

business units of the company<br />

and the most effective interaction<br />

between units during the design,<br />

construction and repair of wells.<br />

BUSINESS-ACCENT<br />

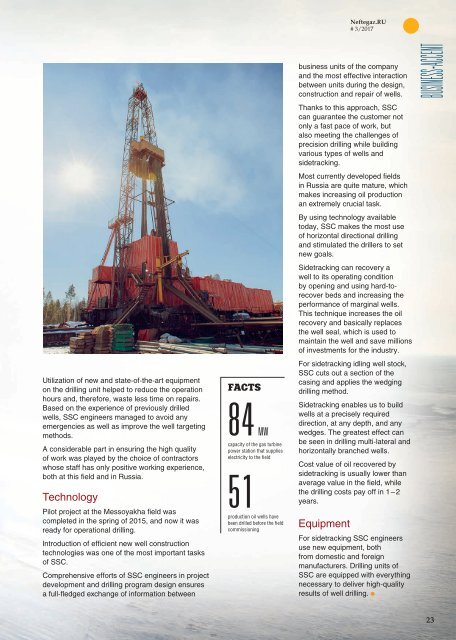

Utilization of new and state-of-the-art equipment<br />

on the drilling unit helped to reduce the operation<br />

hours and, therefore, waste less time on repairs.<br />

Based on the experience of previously drilled<br />

wells, SSC engineers managed to avoid any<br />

emergencies as well as improve the well targeting<br />

methods.<br />

A considerable part in ensuring the high quality<br />

of work was played by the choice of contractors<br />

whose staff has only positive working experience,<br />

both at this field and in Russia.<br />

Technology<br />

Pilot project at the Messoyakha field was<br />

completed in the spring of 2015, and now it was<br />

ready for operational drilling.<br />

Introduction of efficient new well construction<br />

technologies was one of the most important tasks<br />

of SSC.<br />

Comprehensive efforts of SSC engineers in project<br />

development and drilling program design ensures<br />

a full-fledged exchange of information between<br />

FACTS<br />

84 MW<br />

capacity of the gas turbine<br />

power station that supplies<br />

electricity to the field<br />

51<br />

production oil wells have<br />

been drilled before the field<br />

commissioning<br />

Thanks to this approach, SSC<br />

can guarantee the customer not<br />

only a fast pace of work, but<br />

also meeting the challenges of<br />

precision drilling while building<br />

various types of wells and<br />

sidetracking.<br />

Most currently developed fields<br />

in Russia are quite mature, which<br />

makes increasing oil production<br />

an extremely crucial task.<br />

By using technology available<br />

today, SSC makes the most use<br />

of horizontal directional drilling<br />

and stimulated the drillers to set<br />

new goals.<br />

Sidetracking can recovery a<br />

well to its operating condition<br />

by opening and using hard-torecover<br />

beds and increasing the<br />

performance of marginal wells.<br />

This technique increases the oil<br />

recovery and basically replaces<br />

the well seal, which is used to<br />

maintain the well and save millions<br />

of investments for the industry.<br />

For sidetracking idling well stock,<br />

SSC cuts out a section of the<br />

casing and applies the wedging<br />

drilling method.<br />

Sidetracking enables us to build<br />

wells at a precisely required<br />

direction, at any depth, and any<br />

wedges. The greatest effect can<br />

be seen in drilling multi-lateral and<br />

horizontally branched wells.<br />

Cost value of oil recovered by<br />

sidetracking is usually lower than<br />

average value in the field, while<br />

the drilling costs pay off in 1 – 2<br />

years.<br />

Equipment<br />

For sidetracking SSC engineers<br />

use new equipment, both<br />

from domestic and foreign<br />

manufacturers. Drilling units of<br />

SSC are equipped with everything<br />

necessary to deliver high-quality<br />

results of well drilling.<br />

23