Neftegaz.RU #3-17 ENG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRODUCTION<br />

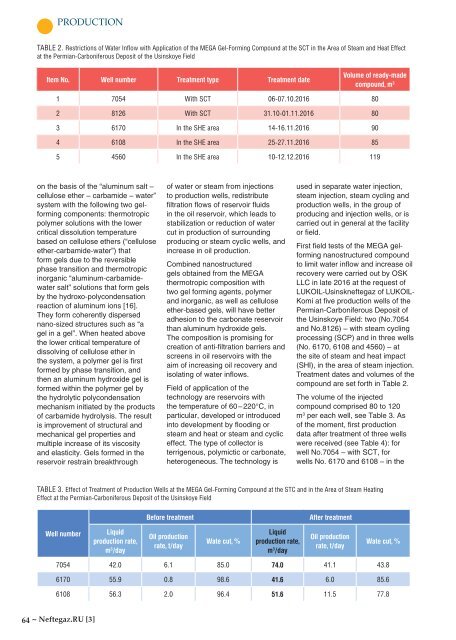

TABLE 2. Restrictions of Water Inflow with Application of the MEGA Gel-Forming Compound at the SCT in the Area of Steam and Heat Effect<br />

at the Permian-Carboniferous Deposit of the Usinskoye Field<br />

Item No. Well number Treatment type Treatment date<br />

Volume of ready-made<br />

compound, m 3<br />

1 7054 With SCT 06-07.10.2016 80<br />

2 8126 With SCT 31.10-01.11.2016 80<br />

3 6<strong>17</strong>0 In the SHE area 14-16.11.2016 90<br />

4 6108 In the SHE area 25-27.11.2016 85<br />

5 4560 In the SHE area 10-12.12.2016 119<br />

on the basis of the “aluminum salt –<br />

cellulose ether – carbamide – water”<br />

system with the following two gelforming<br />

components: thermotropic<br />

polymer solutions with the lower<br />

critical dissolution temperature<br />

based on cellulose ethers (“cellulose<br />

ether-carbamide-water”) that<br />

form gels due to the reversible<br />

phase transition and thermotropic<br />

inorganic “aluminum-carbamidewater<br />

salt” solutions that form gels<br />

by the hydroxo-polycondensation<br />

reaction of aluminum ions [16].<br />

They form coherently dispersed<br />

nano-sized structures such as “a<br />

gel in a gel”. When heated above<br />

the lower critical temperature of<br />

dissolving of cellulose ether in<br />

the system, a polymer gel is first<br />

formed by phase transition, and<br />

then an aluminum hydroxide gel is<br />

formed within the polymer gel by<br />

the hydrolytic polycondensation<br />

mechanism initiated by the products<br />

of carbamide hydrolysis. The result<br />

is improvement of structural and<br />

mechanical gel properties and<br />

multiple increase of its viscosity<br />

and elasticity. Gels formed in the<br />

reservoir restrain breakthrough<br />

of water or steam from injections<br />

to production wells, redistribute<br />

filtration flows of reservoir fluids<br />

in the oil reservoir, which leads to<br />

stabilization or reduction of water<br />

cut in production of surrounding<br />

producing or steam cyclic wells, and<br />

increase in oil production.<br />

Combined nanostructured<br />

gels obtained from the MEGA<br />

thermotropic composition with<br />

two gel forming agents, polymer<br />

and inorganic, as well as cellulose<br />

ether-based gels, will have better<br />

adhesion to the carbonate reservoir<br />

than aluminum hydroxide gels.<br />

The composition is promising for<br />

creation of anti-filtration barriers and<br />

screens in oil reservoirs with the<br />

aim of increasing oil recovery and<br />

isolating of water inflows.<br />

Field of application of the<br />

technology are reservoirs with<br />

the temperature of 60 – 220°С, in<br />

particular, developed or introduced<br />

into development by flooding or<br />

steam and heat or steam and cyclic<br />

effect. The type of collector is<br />

terrigenous, polymictic or carbonate,<br />

heterogeneous. The technology is<br />

used in separate water injection,<br />

steam injection, steam cycling and<br />

production wells, in the group of<br />

producing and injection wells, or is<br />

carried out in general at the facility<br />

or field.<br />

First field tests of the MEGA gelforming<br />

nanostructured compound<br />

to limit water inflow and increase oil<br />

recovery were carried out by OSK<br />

LLC in late 2016 at the request of<br />

LUKOIL-Usinskneftegaz of LUKOIL-<br />

Komi at five production wells of the<br />

Permian-Carboniferous Deposit of<br />

the Usinskoye Field: two (No.7054<br />

and No.8126) – with steam cycling<br />

processing (SCP) and in three wells<br />

(No. 6<strong>17</strong>0, 6108 and 4560) – at<br />

the site of steam and heat impact<br />

(SHI), in the area of steam injection.<br />

Treatment dates and volumes of the<br />

compound are set forth in Table 2.<br />

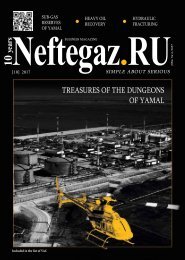

The volume of the injected<br />

compound comprised 80 to 120<br />

m 3 per each well, see Table 3. As<br />

of the moment, first production<br />

data after treatment of three wells<br />

were received (see Table 4): for<br />

well No.7054 – with SCT, for<br />

wells No. 6<strong>17</strong>0 and 6108 – in the<br />

TABLE 3. Effect of Treatment of Production Wells at the MEGA Gel-Forming Compound at the STC and in the Area of Steam Heating<br />

Effect at the Permian-Carboniferous Deposit of the Usinskoye Field<br />

Before treatment<br />

After treatment<br />

Well number<br />

Liquid<br />

production rate,<br />

m 3 /day<br />

Oil production<br />

rate, t/day<br />

Wate cut, %<br />

Liquid<br />

production rate,<br />

m 3 /day<br />

Oil production<br />

rate, t/day<br />

Wate cut, %<br />

7054 42.0 6.1 85.0 74.0 41.1 43.8<br />

6<strong>17</strong>0 55.9 0.8 98.6 41.6 6.0 85.6<br />

6108 56.3 2.0 96.4 51.6 11.5 77.8<br />

64 ~ <strong>Neftegaz</strong>.<strong>RU</strong> [3]