(WIP) ACC 350 Exam 1 Study Material

Work in Process

Work in Process

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

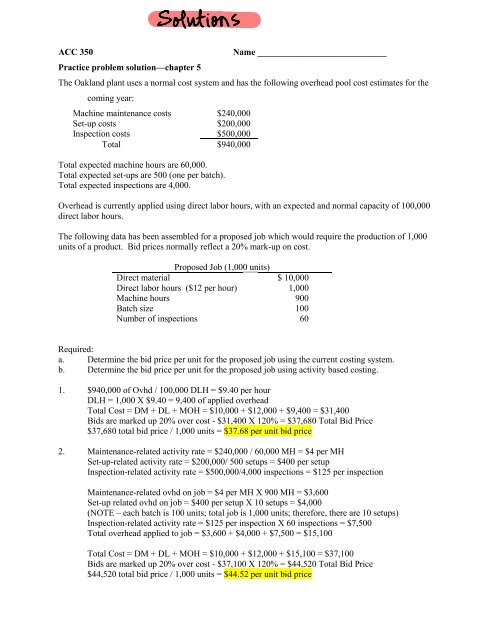

Solutions<br />

<strong>ACC</strong> <strong>350</strong><br />

Practice problem solution—chapter 5<br />

Name _____________________________<br />

The Oakland plant uses a normal cost system and has the following overhead pool cost estimates for the<br />

coming year:<br />

Machine maintenance costs $240,000<br />

Set-up costs $200,000<br />

Inspection costs $500,000<br />

Total $940,000<br />

Total expected machine hours are 60,000.<br />

Total expected set-ups are 500 (one per batch).<br />

Total expected inspections are 4,000.<br />

Overhead is currently applied using direct labor hours, with an expected and normal capacity of 100,000<br />

direct labor hours.<br />

The following data has been assembled for a proposed job which would require the production of 1,000<br />

units of a product. Bid prices normally reflect a 20% mark-up on cost.<br />

Proposed Job (1,000 units)<br />

Direct material $ 10,000<br />

Direct labor hours ($12 per hour) 1,000<br />

Machine hours 900<br />

Batch size 100<br />

Number of inspections 60<br />

Required:<br />

a. Determine the bid price per unit for the proposed job using the current costing system.<br />

b. Determine the bid price per unit for the proposed job using activity based costing.<br />

1. $940,000 of Ovhd / 100,000 DLH = $9.40 per hour<br />

DLH = 1,000 X $9.40 = 9,400 of applied overhead<br />

Total Cost = DM + DL + MOH = $10,000 + $12,000 + $9,400 = $31,400<br />

Bids are marked up 20% over cost - $31,400 X 120% = $37,680 Total Bid Price<br />

$37,680 total bid price / 1,000 units = $37.68 per unit bid price<br />

2. Maintenance-related activity rate = $240,000 / 60,000 MH = $4 per MH<br />

Set-up-related activity rate = $200,000/ 500 setups = $400 per setup<br />

Inspection-related activity rate = $500,000/4,000 inspections = $125 per inspection<br />

Maintenance-related ovhd on job = $4 per MH X 900 MH = $3,600<br />

Set-up related ovhd on job = $400 per setup X 10 setups = $4,000<br />

(NOTE – each batch is 100 units; total job is 1,000 units; therefore, there are 10 setups)<br />

Inspection-related activity rate = $125 per inspection X 60 inspections = $7,500<br />

Total overhead applied to job = $3,600 + $4,000 + $7,500 = $15,100<br />

Total Cost = DM + DL + MOH = $10,000 + $12,000 + $15,100 = $37,100<br />

Bids are marked up 20% over cost - $37,100 X 120% = $44,520 Total Bid Price<br />

$44,520 total bid price / 1,000 units = $44.52 per unit bid price