(WIP) ACC 350 Exam 1 Study Material

Work in Process

Work in Process

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

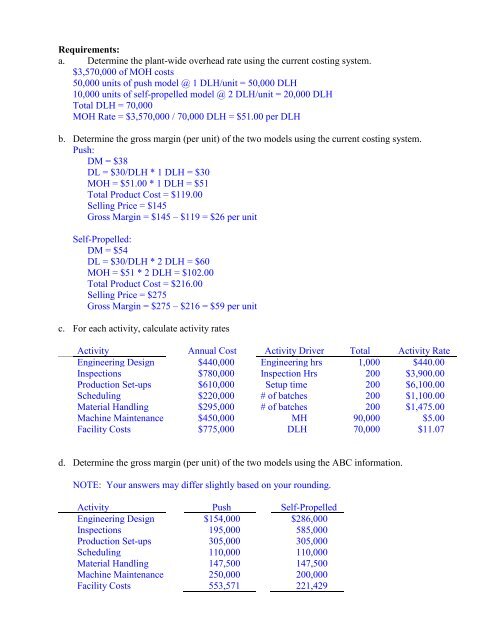

Requirements:<br />

a. Determine the plant-wide overhead rate using the current costing system.<br />

$3,570,000 of MOH costs<br />

50,000 units of push model @ 1 DLH/unit = 50,000 DLH<br />

10,000 units of self-propelled model @ 2 DLH/unit = 20,000 DLH<br />

Total DLH = 70,000<br />

MOH Rate = $3,570,000 / 70,000 DLH = $51.00 per DLH<br />

b. Determine the gross margin (per unit) of the two models using the current costing system.<br />

Push:<br />

DM = $38<br />

DL = $30/DLH * 1 DLH = $30<br />

MOH = $51.00 * 1 DLH = $51<br />

Total Product Cost = $119.00<br />

Selling Price = $145<br />

Gross Margin = $145 – $119 = $26 per unit<br />

Self-Propelled:<br />

DM = $54<br />

DL = $30/DLH * 2 DLH = $60<br />

MOH = $51 * 2 DLH = $102.00<br />

Total Product Cost = $216.00<br />

Selling Price = $275<br />

Gross Margin = $275 – $216 = $59 per unit<br />

c. For each activity, calculate activity rates<br />

Activity Annual Cost Activity Driver Total Activity Rate<br />

Engineering Design $440,000 Engineering hrs 1,000 $440.00<br />

Inspections $780,000 Inspection Hrs 200 $3,900.00<br />

Production Set-ups $610,000 Setup time 200 $6,100.00<br />

Scheduling $220,000 # of batches 200 $1,100.00<br />

<strong>Material</strong> Handling $295,000 # of batches 200 $1,475.00<br />

Machine Maintenance $450,000 MH 90,000 $5.00<br />

Facility Costs $775,000 DLH 70,000 $11.07<br />

d. Determine the gross margin (per unit) of the two models using the ABC information.<br />

NOTE: Your answers may differ slightly based on your rounding.<br />

Activity Push Self-Propelled<br />

Engineering Design $154,000 $286,000<br />

Inspections 195,000 585,000<br />

Production Set-ups 305,000 305,000<br />

Scheduling 110,000 110,000<br />

<strong>Material</strong> Handling 147,500 147,500<br />

Machine Maintenance 250,000 200,000<br />

Facility Costs 553,571 221,429