(WIP) ACC 350 Exam 1 Study Material

Work in Process

Work in Process

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

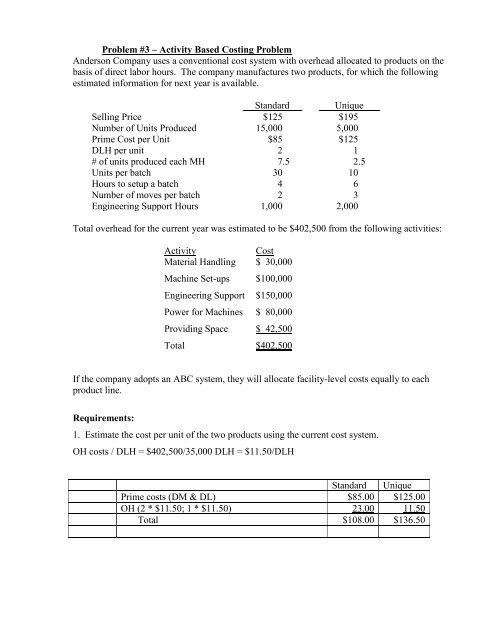

Problem #3 – Activity Based Costing Problem<br />

Anderson Company uses a conventional cost system with overhead allocated to products on the<br />

basis of direct labor hours. The company manufactures two products, for which the following<br />

estimated information for next year is available.<br />

Standard Unique<br />

Selling Price $125 $195<br />

Number of Units Produced 15,000 5,000<br />

Prime Cost per Unit $85 $125<br />

DLH per unit 2 1<br />

# of units produced each MH 7.5 2.5<br />

Units per batch 30 10<br />

Hours to setup a batch 4 6<br />

Number of moves per batch 2 3<br />

Engineering Support Hours 1,000 2,000<br />

Total overhead for the current year was estimated to be $402,500 from the following activities:<br />

Activity<br />

Cost<br />

<strong>Material</strong> Handling $ 30,000<br />

Machine Set-ups $100,000<br />

Engineering Support $150,000<br />

Power for Machines $ 80,000<br />

Providing Space $ 42,500<br />

Total $402,500<br />

If the company adopts an ABC system, they will allocate facility-level costs equally to each<br />

product line.<br />

Requirements:<br />

1. Estimate the cost per unit of the two products using the current cost system.<br />

OH costs / DLH = $402,500/35,000 DLH = $11.50/DLH<br />

Standard Unique<br />

Prime costs (DM & DL) $85.00 $125.00<br />

OH (2 * $11.50; 1 * $11.50) 23.00 11.50<br />

Total $108.00 $136.50