(a) 100 µm - Helmholtz-Zentrum Berlin

(a) 100 µm - Helmholtz-Zentrum Berlin

(a) 100 µm - Helmholtz-Zentrum Berlin

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

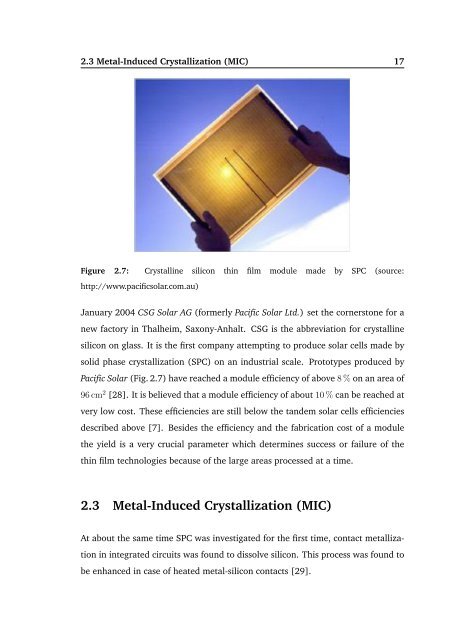

2.3 Metal-Induced Crystallization (MIC) 17<br />

Figure 2.7: Crystalline silicon thin film module made by SPC (source:<br />

http://www.pacificsolar.com.au)<br />

January 2004 CSG Solar AG (formerly Pacific Solar Ltd.) set the cornerstone for a<br />

new factory in Thalheim, Saxony-Anhalt. CSG is the abbreviation for crystalline<br />

silicon on glass. It is the first company attempting to produce solar cells made by<br />

solid phase crystallization (SPC) on an industrial scale. Prototypes produced by<br />

Pacific Solar (Fig. 2.7) have reached a module efficiency of above 8 % on an area of<br />

96 cm 2 [28]. It is believed that a module efficiency of about 10 % can be reached at<br />

very low cost. These efficiencies are still below the tandem solar cells efficiencies<br />

described above [7]. Besides the efficiency and the fabrication cost of a module<br />

the yield is a very crucial parameter which determines success or failure of the<br />

thin film technologies because of the large areas processed at a time.<br />

2.3 Metal-Induced Crystallization (MIC)<br />

At about the same time SPC was investigated for the first time, contact metalliza-<br />

tion in integrated circuits was found to dissolve silicon. This process was found to<br />

be enhanced in case of heated metal-silicon contacts [29].