(a) 100 µm - Helmholtz-Zentrum Berlin

(a) 100 µm - Helmholtz-Zentrum Berlin

(a) 100 µm - Helmholtz-Zentrum Berlin

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

26 State of the art<br />

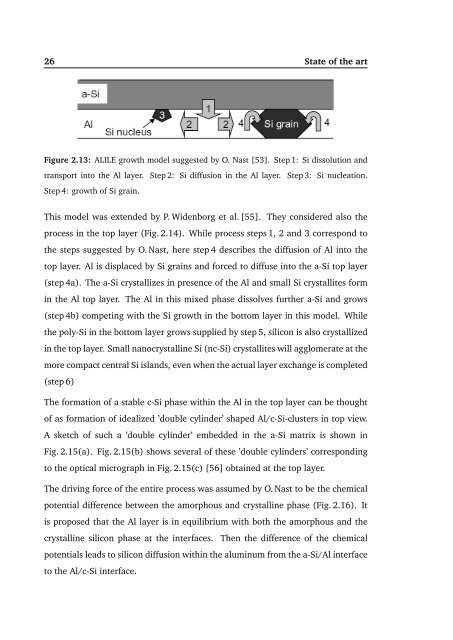

Figure 2.13: ALILE growth model suggested by O. Nast [53]. Step 1: Si dissolution and<br />

transport into the Al layer. Step 2: Si diffusion in the Al layer. Step 3: Si nucleation.<br />

Step 4: growth of Si grain.<br />

This model was extended by P. Widenborg et al. [55]. They considered also the<br />

process in the top layer (Fig. 2.14). While process steps 1, 2 and 3 correspond to<br />

the steps suggested by O. Nast, here step 4 describes the diffusion of Al into the<br />

top layer. Al is displaced by Si grains and forced to diffuse into the a-Si top layer<br />

(step 4a). The a-Si crystallizes in presence of the Al and small Si crystallites form<br />

in the Al top layer. The Al in this mixed phase dissolves further a-Si and grows<br />

(step 4b) competing with the Si growth in the bottom layer in this model. While<br />

the poly-Si in the bottom layer grows supplied by step 5, silicon is also crystallized<br />

in the top layer. Small nanocrystalline Si (nc-Si) crystallites will agglomerate at the<br />

more compact central Si islands, even when the actual layer exchange is completed<br />

(step 6)<br />

The formation of a stable c-Si phase within the Al in the top layer can be thought<br />

of as formation of idealized ’double cylinder’ shaped Al/c-Si-clusters in top view.<br />

A sketch of such a ’double cylinder’ embedded in the a-Si matrix is shown in<br />

Fig. 2.15(a). Fig. 2.15(b) shows several of these ’double cylinders’ corresponding<br />

to the optical micrograph in Fig. 2.15(c) [56] obtained at the top layer.<br />

The driving force of the entire process was assumed by O. Nast to be the chemical<br />

potential difference between the amorphous and crystalline phase (Fig. 2.16). It<br />

is proposed that the Al layer is in equilibrium with both the amorphous and the<br />

crystalline silicon phase at the interfaces. Then the difference of the chemical<br />

potentials leads to silicon diffusion within the aluminum from the a-Si/Al interface<br />

to the Al/c-Si interface.