Forgeabilité des aciers inoxydables austéno-ferritiques

Forgeabilité des aciers inoxydables austéno-ferritiques

Forgeabilité des aciers inoxydables austéno-ferritiques

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tel-00672279, version 1 - 21 Feb 2012<br />

98 Chapter IV. STRAIN PARTITIONING<br />

with the deformation, which may later be observed and measured. It is possible to measure the in-<br />

plane strains at the surface of a specimen by taking images in the undeformed and in the deformed<br />

configuration, and by finding the homologous points in both configurations. Homologous points are the<br />

points in the images (undeformed and deformed) that belong to the same material point on the sam-<br />

ple. The homologous points draw a displacement field, which can be differentiated to get the in-plane<br />

strain fields. The outcome of the procedure depends strongly on the accuracy of the matching proce-<br />

dure, on the density of the homologous points, and on the range of deformations. Several techniques<br />

for defining homologous points are available. Here, it has been chosen to introduce only the two main<br />

image analysis techniques.<br />

IV.1.1 Grid techniques<br />

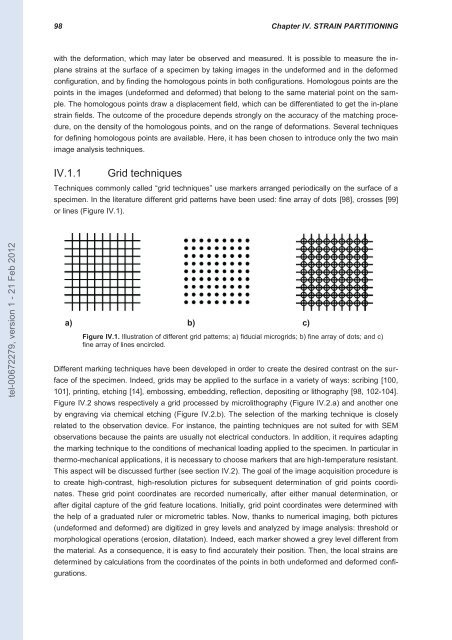

Techniques commonly called “grid techniques” use markers arranged periodically on the surface of a<br />

specimen. In the literature different grid patterns have been used: fine array of dots [98], crosses [99]<br />

or lines (Figure IV.1).<br />

a) b) c)<br />

Figure IV.1. Illustration of different grid patterns; a) fiducial microgrids; b) fine array of dots; and c)<br />

fine array of lines encircled.<br />

Different marking techniques have been developed in order to create the <strong>des</strong>ired contrast on the sur-<br />

face of the specimen. Indeed, grids may be applied to the surface in a variety of ways: scribing [100,<br />

101], printing, etching [14], embossing, embedding, reflection, depositing or lithography [98, 102-104].<br />

Figure IV.2 shows respectively a grid processed by microlithography (Figure IV.2.a) and another one<br />

by engraving via chemical etching (Figure IV.2.b). The selection of the marking technique is closely<br />

related to the observation device. For instance, the painting techniques are not suited for with SEM<br />

observations because the paints are usually not electrical conductors. In addition, it requires adapting<br />

the marking technique to the conditions of mechanical loading applied to the specimen. In particular in<br />

thermo-mechanical applications, it is necessary to choose markers that are high-temperature resistant.<br />

This aspect will be discussed further (see section IV.2). The goal of the image acquisition procedure is<br />

to create high-contrast, high-resolution pictures for subsequent determination of grid points coordi-<br />

nates. These grid point coordinates are recorded numerically, after either manual determination, or<br />

after digital capture of the grid feature locations. Initially, grid point coordinates were determined with<br />

the help of a graduated ruler or micrometric tables. Now, thanks to numerical imaging, both pictures<br />

(undeformed and deformed) are digitized in grey levels and analyzed by image analysis: threshold or<br />

morphological operations (erosion, dilatation). Indeed, each marker showed a grey level different from<br />

the material. As a consequence, it is easy to find accurately their position. Then, the local strains are<br />

determined by calculations from the coordinates of the points in both undeformed and deformed confi-<br />

gurations.