Forgeabilité des aciers inoxydables austéno-ferritiques

Forgeabilité des aciers inoxydables austéno-ferritiques

Forgeabilité des aciers inoxydables austéno-ferritiques

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tel-00672279, version 1 - 21 Feb 2012<br />

100 Chapter IV. STRAIN PARTITIONING<br />

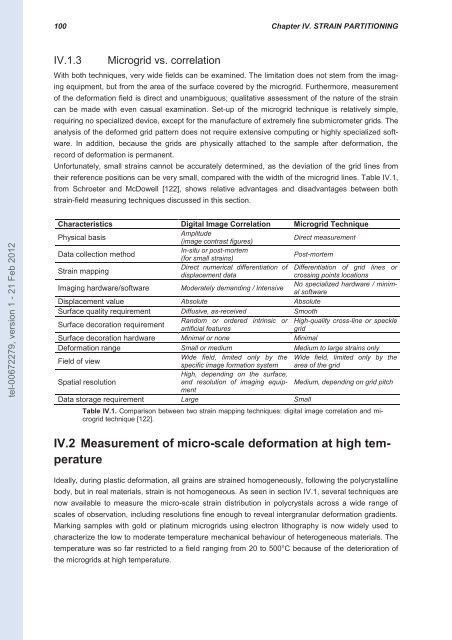

IV.1.3 Microgrid vs. correlation<br />

With both techniques, very wide fields can be examined. The limitation does not stem from the imag-<br />

ing equipment, but from the area of the surface covered by the microgrid. Furthermore, measurement<br />

of the deformation field is direct and unambiguous; qualitative assessment of the nature of the strain<br />

can be made with even casual examination. Set-up of the microgrid technique is relatively simple,<br />

requiring no specialized device, except for the manufacture of extremely fine submicrometer grids. The<br />

analysis of the deformed grid pattern does not require extensive computing or highly specialized soft-<br />

ware. In addition, because the grids are physically attached to the sample after deformation, the<br />

record of deformation is permanent.<br />

Unfortunately, small strains cannot be accurately determined, as the deviation of the grid lines from<br />

their reference positions can be very small, compared with the width of the microgrid lines. Table IV.1,<br />

from Schroeter and McDowell [122], shows relative advantages and disadvantages between both<br />

strain-field measuring techniques discussed in this section.<br />

Characteristics Digital Image Correlation Microgrid Technique<br />

Physical basis<br />

Amplitude<br />

(image contrast figures)<br />

Direct measurement<br />

Data collection method<br />

In-situ or post-mortem<br />

(for small strains)<br />

Post-mortem<br />

Strain mapping<br />

Direct numerical differentiation of<br />

displacement data<br />

Differentiation of grid lines or<br />

crossing points locations<br />

Imaging hardware/software Moderately demanding / Intensive<br />

No specialized hardware / minimal<br />

software<br />

Displacement value Absolute Absolute<br />

Surface quality requirement Diffusive, as-received Smooth<br />

Surface decoration requirement<br />

Random or ordered intrinsic or<br />

artificial features<br />

High-quality cross-line or speckle<br />

grid<br />

Surface decoration hardware Minimal or none Minimal<br />

Deformation range Small or medium Medium to large strains only<br />

Field of view<br />

Wide field, limited only by the<br />

specific image formation system<br />

High, depending on the surface,<br />

Wide field, limited only by the<br />

area of the grid<br />

Spatial resolution<br />

and resolution of imaging equipment<br />

Medium, depending on grid pitch<br />

Data storage requirement Large Small<br />

Table IV.1. Comparison between two strain mapping techniques: digital image correlation and microgrid<br />

technique [122].<br />

IV.2 Measurement of micro-scale deformation at high temperature<br />

Ideally, during plastic deformation, all grains are strained homogeneously, following the polycrystalline<br />

body, but in real materials, strain is not homogeneous. As seen in section IV.1, several techniques are<br />

now available to measure the micro-scale strain distribution in polycrystals across a wide range of<br />

scales of observation, including resolutions fine enough to reveal intergranular deformation gradients.<br />

Marking samples with gold or platinum microgrids using electron lithography is now widely used to<br />

characterize the low to moderate temperature mechanical behaviour of heterogeneous materials. The<br />

temperature was so far restricted to a field ranging from 20 to 500°C because of the deterioration of<br />

the microgrids at high temperature.