Forgeabilité des aciers inoxydables austéno-ferritiques

Forgeabilité des aciers inoxydables austéno-ferritiques

Forgeabilité des aciers inoxydables austéno-ferritiques

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tel-00672279, version 1 - 21 Feb 2012<br />

164 Chapter V. CONCLUSIONS and PERSPECTIVES<br />

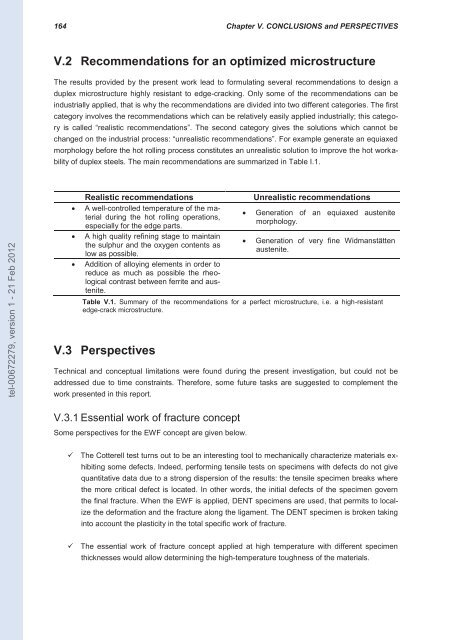

V.2 Recommendations for an optimized microstructure<br />

The results provided by the present work lead to formulating several recommendations to <strong>des</strong>ign a<br />

duplex microstructure highly resistant to edge-cracking. Only some of the recommendations can be<br />

industrially applied, that is why the recommendations are divided into two different categories. The first<br />

category involves the recommendations which can be relatively easily applied industrially; this catego-<br />

ry is called “realistic recommendations”. The second category gives the solutions which cannot be<br />

changed on the industrial process: “unrealistic recommendations”. For example generate an equiaxed<br />

morphology before the hot rolling process constitutes an unrealistic solution to improve the hot worka-<br />

bility of duplex steels. The main recommendations are summarized in Table I.1.<br />

Realistic recommendations Unrealistic recommendations<br />

� A well-controlled temperature of the material<br />

during the hot rolling operations,<br />

especially for the edge parts.<br />

� A high quality refining stage to maintain<br />

the sulphur and the oxygen contents as<br />

low as possible.<br />

� Addition of alloying elements in order to<br />

reduce as much as possible the rheological<br />

contrast between ferrite and austenite.<br />

� Generation of an equiaxed austenite<br />

morphology.<br />

� Generation of very fine Widmanstätten<br />

austenite.<br />

Table V.1. Summary of the recommendations for a perfect microstructure, i.e. a high-resistant<br />

edge-crack microstructure.<br />

V.3 Perspectives<br />

Technical and conceptual limitations were found during the present investigation, but could not be<br />

addressed due to time constraints. Therefore, some future tasks are suggested to complement the<br />

work presented in this report.<br />

V.3.1 Essential work of fracture concept<br />

Some perspectives for the EWF concept are given below.<br />

� The Cotterell test turns out to be an interesting tool to mechanically characterize materials ex-<br />

hibiting some defects. Indeed, performing tensile tests on specimens with defects do not give<br />

quantitative data due to a strong dispersion of the results: the tensile specimen breaks where<br />

the more critical defect is located. In other words, the initial defects of the specimen govern<br />

the final fracture. When the EWF is applied, DENT specimens are used, that permits to local-<br />

ize the deformation and the fracture along the ligament. The DENT specimen is broken taking<br />

into account the plasticity in the total specific work of fracture.<br />

� The essential work of fracture concept applied at high temperature with different specimen<br />

thicknesses would allow determining the high-temperature toughness of the materials.