Configuration Manual Synchronous Motors 1FT6 - Siemens ...

Configuration Manual Synchronous Motors 1FT6 - Siemens ...

Configuration Manual Synchronous Motors 1FT6 - Siemens ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Motor Description<br />

1.7 Cooling<br />

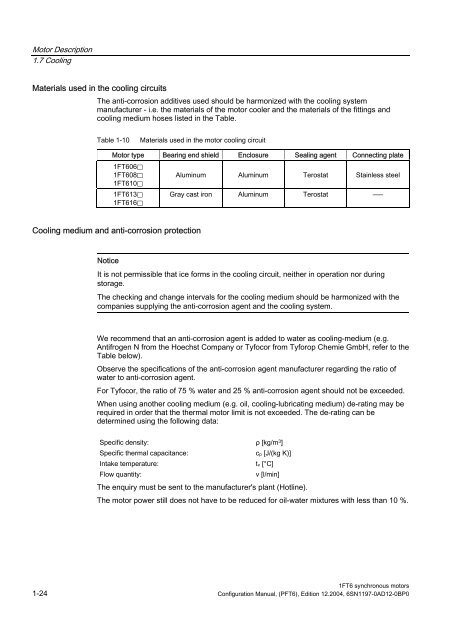

Materials used in the cooling circuits<br />

The anti-corrosion additives used should be harmonized with the cooling system<br />

manufacturer - i.e. the materials of the motor cooler and the materials of the fittings and<br />

cooling medium hoses listed in the Table.<br />

Table 1-10 Materials used in the motor cooling circuit<br />

Motor type Bearing end shield Enclosure Sealing agent Connecting plate<br />

<strong>1FT6</strong>06⃞<br />

<strong>1FT6</strong>08⃞<br />

<strong>1FT6</strong>10⃞<br />

<strong>1FT6</strong>13⃞<br />

<strong>1FT6</strong>16⃞<br />

Aluminum<br />

Cooling medium and anti-corrosion protection<br />

Notice<br />

Aluminum<br />

Terostat<br />

Stainless steel<br />

Gray cast iron Aluminum Terostat –––<br />

It is not permissible that ice forms in the cooling circuit, neither in operation nor during<br />

storage.<br />

The checking and change intervals for the cooling medium should be harmonized with the<br />

companies supplying the anti-corrosion agent and the cooling system.<br />

We recommend that an anti-corrosion agent is added to water as cooling-medium (e.g.<br />

Antifrogen N from the Hoechst Company or Tyfocor from Tyforop Chemie GmbH, refer to the<br />

Table below).<br />

Observe the specifications of the anti-corrosion agent manufacturer regarding the ratio of<br />

water to anti-corrosion agent.<br />

For Tyfocor, the ratio of 75 % water and 25 % anti-corrosion agent should not be exceeded.<br />

When using another cooling medium (e.g. oil, cooling-lubricating medium) de-rating may be<br />

required in order that the thermal motor limit is not exceeded. The de-rating can be<br />

determined using the following data:<br />

Specific density: ρ [kg/m 3 ]<br />

Specific thermal capacitance: cp [J/(kg K)]<br />

Intake temperature: tv [°C]<br />

Flow quantity: v [l/min]<br />

The enquiry must be sent to the manufacturer's plant (Hotline).<br />

The motor power still does not have to be reduced for oil-water mixtures with less than 10 %.<br />

<strong>1FT6</strong> synchronous motors<br />

1-24 <strong>Configuration</strong> <strong>Manual</strong>, (PFT6), Edition 12.2004, 6SN1197-0AD12-0BP0