Janoschka magazine Linked_V8_2023

The customer magazine by Janoschka and Linked2Brands.

The customer magazine by Janoschka and Linked2Brands.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

34 f a c e t o f a c e<br />

issue #8 © l i n k e d 35<br />

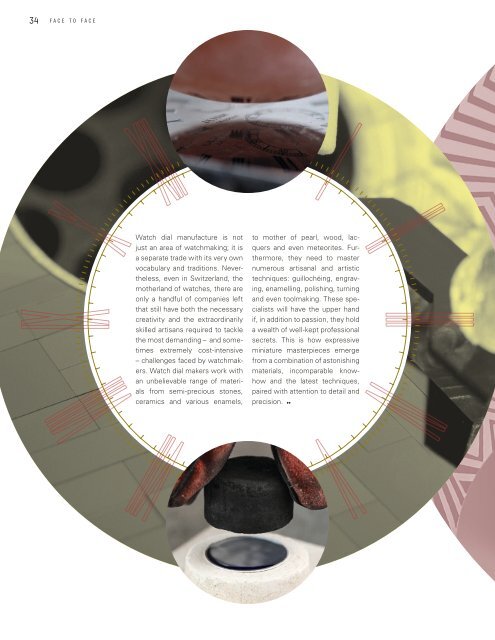

Thh e divisions on a watch dial allow us to measure time precisely down to fractions of a second. Th h e indices, windows and sub-dials allow us to keep an eye on the time, day, date, month and year as well as follow the phases of the moon.<br />

METICULOUS CARE<br />

Watch dial manufacture is not<br />

just an area of watchmaking; it is<br />

a separate trade with its very own<br />

vocabulary and traditions. Nevertheless,<br />

even in Switzerland, the<br />

motherland of watches, there are<br />

only a handful of companies left<br />

that still have both the necessary<br />

creativity and the extraordinarily<br />

skilled artisans required to tackle<br />

the most demanding – and sometimes<br />

extremely cost-intensive<br />

– challenges faced by watchmakers.<br />

Watch dial makers work with<br />

an unbelievable range of materials<br />

from semi-precious stones,<br />

ceramics and various enamels,<br />

to mother of pearl, wood, lacquers<br />

and even meteorites. Furthermore,<br />

they need to master<br />

numerous artisanal and artistic<br />

techniques: guillochéing, engraving,<br />

enamelling, polishing, turning<br />

and even toolmaking. These specialists<br />

will have the upper hand<br />

if, in addition to passion, they hold<br />

a wealth of well-kept professional<br />

secrets. This is how expressive<br />

miniature masterpieces emerge<br />

from a combination of astonishing<br />

materials, incomparable knowhow<br />

and the latest techniques,<br />

paired with attention to detail and<br />

precision.<br />

Each watch dial model is unique and<br />

defined by its style, functions and<br />

components, like date display, totalisators<br />

(sub-dials), moon phase indicators<br />

– and the way these are positioned.<br />

Once the design has been finalised,<br />

the dial-maker starts with a blank: a<br />

thin metal disc made from brass, nickel,<br />

gold, silver, titanium or similar. After<br />

a few preparations, which include<br />

punching out the display windows and<br />

the hole in the centre for the hands,<br />

they attach small feet to the back of<br />

the metal disc. These appendages<br />

eventually anchor the watch face to<br />

the movement. Initially, though, their<br />

job is to ensure accurate positioning<br />

of the dial during the subsequent assembly<br />

stages. The blanks are then<br />

cleaned and polished before setting<br />

out on a journey into a world of diverse<br />

and highly specialised craftsmanship.<br />

Along the way, some will be adorned<br />

with decorative finishes (like the famous<br />

sunbrushing); others may stop<br />

off at the electroplating department<br />

for metal-plated enhancements; while<br />

others still will receive their final colour<br />

in the paint shop.<br />

Let’s take a closer look at a few special<br />

surface refinements. Some have<br />

been used for centuries, while others<br />

are state-of-the-art. Meticulous craftsmanship<br />

is involved as well as the<br />

latest advanced precision tools. Both<br />

serve to produce watch dials with a<br />

perfect balance of beauty and clear<br />

readability.