Janoschka magazine Linked_V8_2023

The customer magazine by Janoschka and Linked2Brands.

The customer magazine by Janoschka and Linked2Brands.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

86 n o t e s<br />

issue #8 ©<br />

l i n k e d<br />

87<br />

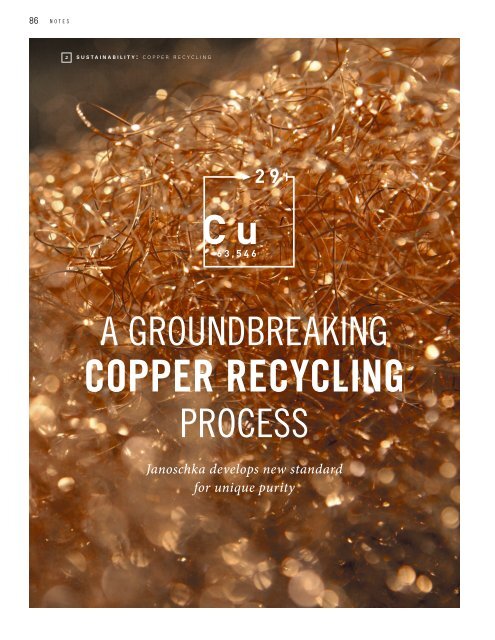

2 s u s t a i n a b i l i t y : c o p p e r r e c y c l i n g<br />

29<br />

C u<br />

63,546<br />

A GROUNDBREAKING<br />

COPPER RECYCLING<br />

PROCESS<br />

<strong>Janoschka</strong> develops new standard<br />

for unique purity<br />

When it comes to printing packaging, catalogues<br />

and <strong>magazine</strong>s in large batches, gravure cylinders<br />

are unbeatable. They produce precise and reliably<br />

consistent printing results – economically, efficiently<br />

and at high speed. A key component of a gravure<br />

cylinder is the thin layer of copper that is applied to<br />

the cylinder base with a thickness in the µ range.<br />

It has the perfect properties for engraving the cylinder<br />

during the electromechanical imaging process.<br />

A final layer of chrome ensures a long life. Once<br />

the print job is complete, gravure cylinders can be<br />

reused over and over again.<br />

99.98 %<br />

pure copper<br />

Copper is a durable material that has the highest<br />

rate of recycling across the world. Copper<br />

recycling has a long tradition and works over<br />

and over again without any noticeable loss<br />

in quality or properties. Nothing new about<br />

that. The <strong>Janoschka</strong> process, however, is<br />

unique because of the purity standards it<br />

delivers and the small nugget form.<br />

The old copper layer and thus the print design is<br />

removed so that a fresh layer of copper can then be<br />

added for a new engraving.<br />

This method of recycling has inspired <strong>Janoschka</strong><br />

to become a pioneer in terms of sustainability and<br />

go one step further. In an extensive research project,<br />

<strong>Janoschka</strong> Izmir collaborated with a university<br />

department for material technology to develop a<br />

unique recycling process for extracting 99.98 per<br />

cent pure copper.<br />

7t<br />

per month<br />

Six to eight tonnes of copper are now being<br />

recycled at <strong>Janoschka</strong> Izmir each month.<br />

Investments in two other recycling centres<br />

within <strong>Janoschka</strong> Group are currently being<br />

planned.<br />

As a world leader, <strong>Janoschka</strong> has committed<br />

itself to constant innovation and sustainability.<br />

Setting an example in the sector, we<br />

translate words into deeds, thus reducing<br />

the environmental impact of our activities.<br />

Our own copper recycling alone yields annual<br />

carbon savings of over 235 tonnes.