Janoschka magazine Linked_V8_2023

The customer magazine by Janoschka and Linked2Brands.

The customer magazine by Janoschka and Linked2Brands.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

40<br />

f a c e t o f a c e<br />

issue #8 ©<br />

l i n k e d<br />

41<br />

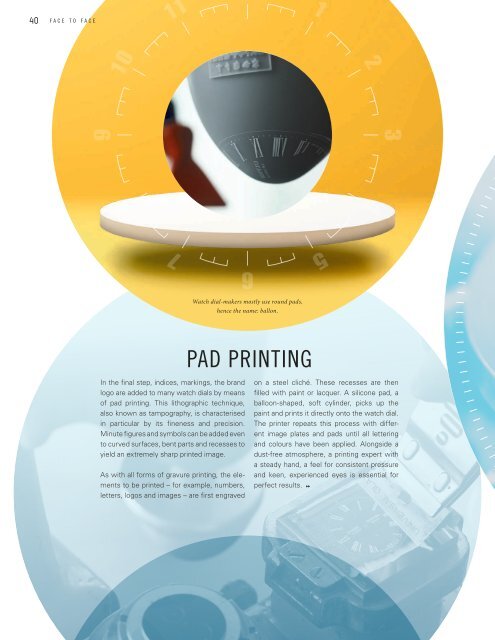

Watch dial-makers mostly use round pads,<br />

hence the name: ballon.<br />

PAD PRINTING<br />

All techniques used to create<br />

watch dials have one thing<br />

in common: high quality and<br />

know-how are of paramount<br />

importance for each individual<br />

part and for all the materials and<br />

every manufacturing step.<br />

In addition to highly specialised<br />

and high-performance equipment,<br />

it is the skilled hands of<br />

artisans who lend the blanks a<br />

unique identity on their journey<br />

through the different crafts.<br />

The end result is the finished<br />

watch dial, which translates the<br />

concealed tiny world of wheels,<br />

levers, pins and springs into<br />

readable time and endows the<br />

many hundred individual parts<br />

of a watch with a meaning.<br />

In the final step, indices, markings, the brand<br />

logo are added to many watch dials by means<br />

of pad printing. This lithographic technique,<br />

also known as tampography, is characterised<br />

in particular by its fineness and precision.<br />

Minute figures and symbols can be added even<br />

to curved surfaces, bent parts and recesses to<br />

yield an extremely sharp printed image.<br />

As with all forms of gravure printing, the elements<br />

to be printed – for example, numbers,<br />

letters, logos and images – are first engraved<br />

on a steel cliché. These recesses are then<br />

filled with paint or lacquer. A silicone pad, a<br />

balloon-shaped, soft cylinder, picks up the<br />

paint and prints it directly onto the watch dial.<br />

The printer repeats this process with different<br />

image plates and pads until all lettering<br />

and colours have been applied. Alongside a<br />

dust-free atmosphere, a printing expert with<br />

a steady hand, a feel for consistent pressure<br />

and keen, experienced eyes is essential for<br />

perfect results.<br />

ulysse-nardin.com