SPRING 2024

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

126<br />

THE DISTRIBUTOR’S LINK<br />

LAURENCE CLAUS HOW FASTENERS ARE MADE - PART 2: HOT HEADING AND SCREW MACHINING from page 84<br />

parts provided the operator or machine can hold the blank<br />

steady during the forming process. Usually, the first blow<br />

forms the head shape, and the second blow creates any<br />

required head markings.<br />

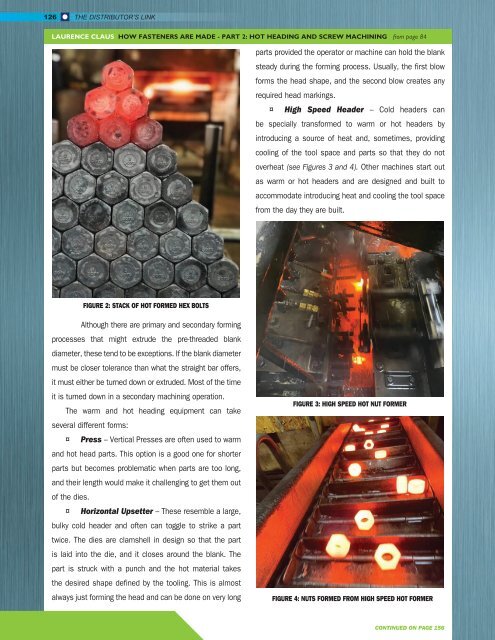

¤ High Speed Header – Cold headers can<br />

be specially transformed to warm or hot headers by<br />

introducing a source of heat and, sometimes, providing<br />

cooling of the tool space and parts so that they do not<br />

overheat (see Figures 3 and 4). Other machines start out<br />

as warm or hot headers and are designed and built to<br />

accommodate introducing heat and cooling the tool space<br />

from the day they are built.<br />

FIGURE 2: STACK OF HOT FORMED HEX BOLTS<br />

Although there are primary and secondary forming<br />

processes that might extrude the pre-threaded blank<br />

diameter, these tend to be exceptions. If the blank diameter<br />

must be closer tolerance than what the straight bar offers,<br />

it must either be turned down or extruded. Most of the time<br />

it is turned down in a secondary machining operation.<br />

The warm and hot heading equipment can take<br />

several different forms:<br />

¤ Press – Vertical Presses are often used to warm<br />

and hot head parts. This option is a good one for shorter<br />

parts but becomes problematic when parts are too long,<br />

and their length would make it challenging to get them out<br />

of the dies.<br />

¤ Horizontal Upsetter – These resemble a large,<br />

bulky cold header and often can toggle to strike a part<br />

twice. The dies are clamshell in design so that the part<br />

is laid into the die, and it closes around the blank. The<br />

part is struck with a punch and the hot material takes<br />

the desired shape defined by the tooling. This is almost<br />

always just forming the head and can be done on very long<br />

FIGURE 3: HIGH SPEED HOT NUT FORMER<br />

FIGURE 4: NUTS FORMED FROM HIGH SPEED HOT FORMER<br />

CONTINUED ON PAGE 156