SPRING 2024

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

90<br />

THE DISTRIBUTOR’S LINK<br />

ROB LaPOINTE FASTENER SCIENCE: THE ROLE OF CARBON IN STEEL from page 14<br />

Low Alloy Steel<br />

Low alloy steel consists of low carbon, medium<br />

carbon, and high carbon steels where carbon is the<br />

main alloying element. Low carbon steel (0.04-0.3 %<br />

C) has the lowest hardenability of low alloy steels. It<br />

is characterized by its flexibility, machinability, and<br />

low cost. SAE J429, grades 1 and 2 can be produced<br />

from low carbon steel and do not need heat treatment<br />

to achieve the tensile performance characteristics of<br />

60,000 psi and 74,000 psi respectively.<br />

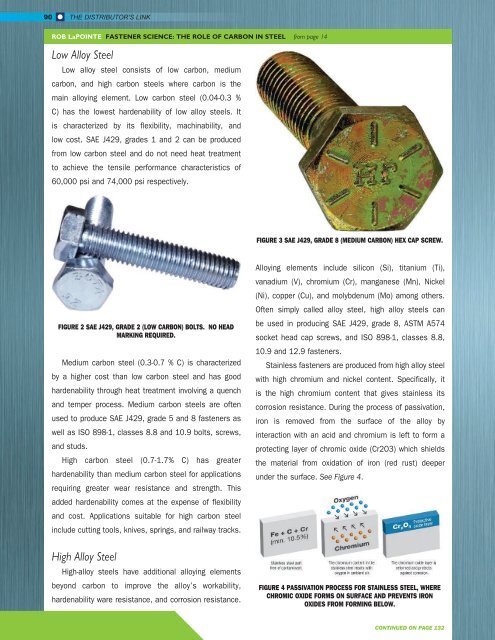

FIGURE 3 SAE J429, GRADE 8 (MEDIUM CARBON) HEX CAP SCREW.<br />

FIGURE 2 SAE J429, GRADE 2 (LOW CARBON) BOLTS. NO HEAD<br />

MARKING REQUIRED.<br />

Medium carbon steel (0.3-0.7 % C) is characterized<br />

by a higher cost than low carbon steel and has good<br />

hardenability through heat treatment involving a quench<br />

and temper process. Medium carbon steels are often<br />

used to produce SAE J429, grade 5 and 8 fasteners as<br />

well as ISO 898-1, classes 8.8 and 10.9 bolts, screws,<br />

and studs.<br />

High carbon steel (0.7-1.7% C) has greater<br />

hardenability than medium carbon steel for applications<br />

requiring greater wear resistance and strength. This<br />

added hardenability comes at the expense of flexibility<br />

and cost. Applications suitable for high carbon steel<br />

include cutting tools, knives, springs, and railway tracks.<br />

High Alloy Steel<br />

High-alloy steels have additional alloying elements<br />

beyond carbon to improve the alloy’s workability,<br />

hardenability ware resistance, and corrosion resistance.<br />

Alloying elements include silicon (Si), titanium (Ti),<br />

vanadium (V), chromium (Cr), manganese (Mn), Nickel<br />

(Ni), copper (Cu), and molybdenum (Mo) among others.<br />

Often simply called alloy steel, high alloy steels can<br />

be used in producing SAE J429, grade 8, ASTM A574<br />

socket head cap screws, and ISO 898-1, classes 8.8,<br />

10.9 and 12.9 fasteners.<br />

Stainless fasteners are produced from high alloy steel<br />

with high chromium and nickel content. Specifically, it<br />

is the high chromium content that gives stainless its<br />

corrosion resistance. During the process of passivation,<br />

iron is removed from the surface of the alloy by<br />

interaction with an acid and chromium is left to form a<br />

protecting layer of chromic oxide (Cr2O3) which shields<br />

the material from oxidation of iron (red rust) deeper<br />

under the surface. See Figure 4.<br />

FIGURE 4 PASSIVATION PROCESS FOR STAINLESS STEEL, WHERE<br />

CHROMIC OXIDE FORMS ON SURFACE AND PREVENTS IRON<br />

OXIDES FROM FORMING BELOW.<br />

CONTINUED ON PAGE 132