SPRING 2024

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

94<br />

THE DISTRIBUTOR’S LINK<br />

GUY AVELLON WHAT DISTRIBUTORS NEED TO KNOW ABOUT HOW FASTENERS ARE TIGHTENED IN MAINTENANCE ASSEMBLIES from page 26<br />

This would mean that at the same torque, the<br />

cadmium plated lock nuts would produce more tensile<br />

load on the fastener, with the potential of stretching the<br />

fastener into yield, than the zinc plated lock nut. The<br />

connection would be compromised. Some maintenance<br />

shops and those performing field repair work will use<br />

a micrometer adjustable torque wrench. This is also<br />

referred to as a ‘click-type’, where the torque value<br />

is numerically adjusted on the handle. The wrench<br />

will produce an audible ‘click’, which can also be felt,<br />

when the set torque value is reached. At this point, the<br />

operator stops turning the wrench. However, there is no<br />

provision for preventing the operator to continue turning<br />

the wrench and applying more torque to the fastener<br />

which will increase the load on the fastener joint. There<br />

are special adjustable torque wrenches available that<br />

have a cam in the head that will prevent over tightening.<br />

Realistically, most of the maintenance performed<br />

on fasteners is done without using a torque wrench but<br />

with the ‘calibrated elbow’. And, many times using either<br />

the torque wrench or elbow, the tightening procedure is<br />

incorrect.<br />

Torque charts have been printed as guides to<br />

achieving the proper tension on the bolt but it may not<br />

be as perfect for the connection or overall joint. We can<br />

achieve adequate tension on one bolt, but what about<br />

multiple fasteners in the joint? What about environmental<br />

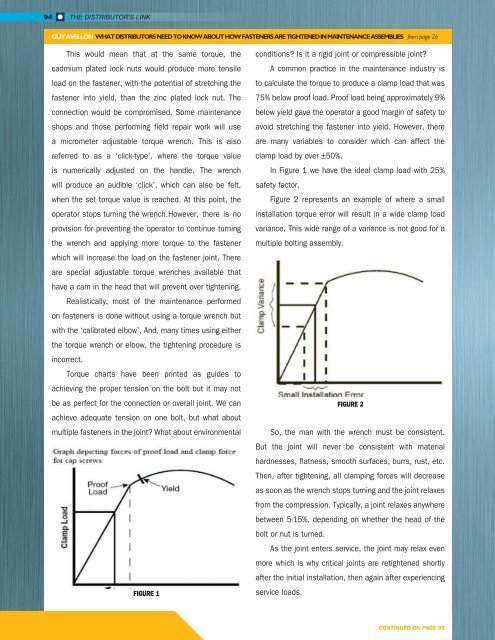

FIGURE 1<br />

conditions? Is it a rigid joint or compressible joint?<br />

A common practice in the maintenance industry is<br />

to calculate the torque to produce a clamp load that was<br />

75% below proof load. Proof load being approximately 9%<br />

below yield gave the operator a good margin of safety to<br />

avoid stretching the fastener into yield. However, there<br />

are many variables to consider which can affect the<br />

clamp load by over ±50%.<br />

In Figure 1 we have the ideal clamp load with 25%<br />

safety factor.<br />

Figure 2 represents an example of where a small<br />

installation torque error will result in a wide clamp load<br />

variance. This wide range of a variance is not good for a<br />

multiple bolting assembly.<br />

FIGURE 2<br />

So, the man with the wrench must be consistent.<br />

But the joint will never be consistent with material<br />

hardnesses, flatness, smooth surfaces, burrs, rust, etc.<br />

Then, after tightening, all clamping forces will decrease<br />

as soon as the wrench stops turning and the joint relaxes<br />

from the compression. Typically, a joint relaxes anywhere<br />

between 5-15%, depending on whether the head of the<br />

bolt or nut is turned.<br />

As the joint enters service, the joint may relax even<br />

more which is why critical joints are retightened shortly<br />

after the initial installation, then again after experiencing<br />

service loads.<br />

CONTINUED ON PAGE 95