SPRING 2024

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

96<br />

THE DISTRIBUTOR’S LINK<br />

BRUNO MARBACHER LOCKING FEATURES TO PREVENT ROTATIONAL LOOSENING from page 28<br />

Ribbed lock washers are made of hardened spring<br />

steel. They ought not to be electro plated to prevent<br />

hydrogen embitterment. They should be mechanically<br />

plated, or zinc flake coated.<br />

There are specific requirements that must be met<br />

during assembly to assure these lock washers are doing<br />

their job.<br />

There are different types of ribbed lock washers,<br />

based on their shapes they have different functions.<br />

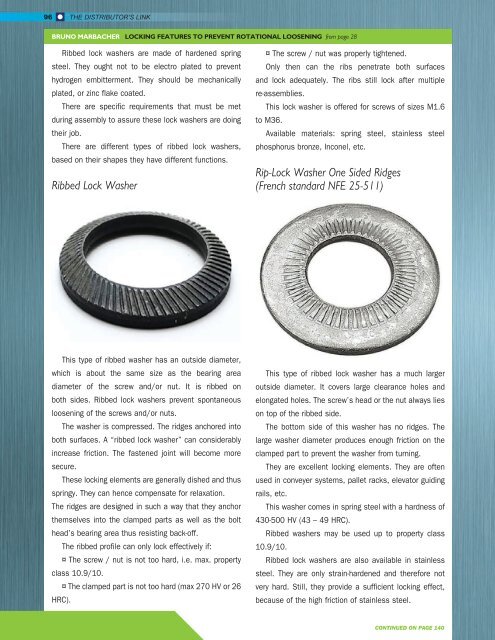

Ribbed Lock Washer<br />

¤ The screw / nut was properly tightened.<br />

Only then can the ribs penetrate both surfaces<br />

and lock adequately. The ribs still lock after multiple<br />

re-assemblies.<br />

This lock washer is offered for screws of sizes M1.6<br />

to M36.<br />

Available materials: spring steel, stainless steel<br />

phosphorus bronze, Inconel, etc.<br />

Rip-Lock Washer One Sided Ridges<br />

(French standard NFE 25-511)<br />

This type of ribbed washer has an outside diameter,<br />

which is about the same size as the bearing area<br />

diameter of the screw and/or nut. It is ribbed on<br />

both sides. Ribbed lock washers prevent spontaneous<br />

loosening of the screws and/or nuts.<br />

The washer is compressed. The ridges anchored into<br />

both surfaces. A “ribbed lock washer” can considerably<br />

increase friction. The fastened joint will become more<br />

secure.<br />

These locking elements are generally dished and thus<br />

springy. They can hence compensate for relaxation.<br />

The ridges are designed in such a way that they anchor<br />

themselves into the clamped parts as well as the bolt<br />

head’s bearing area thus resisting back-off.<br />

The ribbed profile can only lock effectively if:<br />

¤ The screw / nut is not too hard, i.e. max. property<br />

class 10.9/10.<br />

¤ The clamped part is not too hard (max 270 HV or 26<br />

HRC).<br />

This type of ribbed lock washer has a much larger<br />

outside diameter. It covers large clearance holes and<br />

elongated holes. The screw’s head or the nut always lies<br />

on top of the ribbed side.<br />

The bottom side of this washer has no ridges. The<br />

large washer diameter produces enough friction on the<br />

clamped part to prevent the washer from turning.<br />

They are excellent locking elements. They are often<br />

used in conveyer systems, pallet racks, elevator guiding<br />

rails, etc.<br />

This washer comes in spring steel with a hardness of<br />

430-500 HV (43 – 49 HRC).<br />

Ribbed washers may be used up to property class<br />

10.9/10.<br />

Ribbed lock washers are also available in stainless<br />

steel. They are only strain-hardened and therefore not<br />

very hard. Still, they provide a sufficient locking effect,<br />

because of the high friction of stainless steel.<br />

CONTINUED ON PAGE 140