SPRING 2024

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

140<br />

THE DISTRIBUTOR’S LINK<br />

BRUNO MARBACHER LOCKING FEATURES TO PREVENT ROTATIONAL LOOSENING from page 96<br />

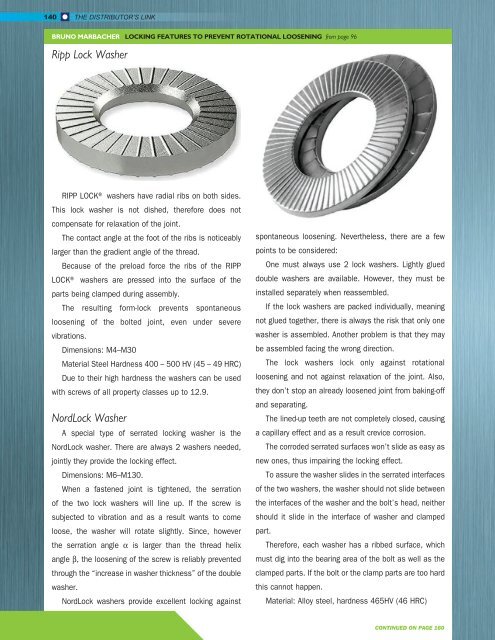

Ripp Lock Washer<br />

RIPP LOCK® washers have radial ribs on both sides.<br />

This lock washer is not dished, therefore does not<br />

compensate for relaxation of the joint.<br />

The contact angle at the foot of the ribs is noticeably<br />

larger than the gradient angle of the thread.<br />

Because of the preload force the ribs of the RIPP<br />

LOCK® washers are pressed into the surface of the<br />

parts being clamped during assembly.<br />

The resulting form-lock prevents spontaneous<br />

loosening of the bolted joint, even under severe<br />

vibrations.<br />

Dimensions: M4–M30<br />

Material Steel Hardness 400 – 500 HV (45 – 49 HRC)<br />

Due to their high hardness the washers can be used<br />

with screws of all property classes up to 12.9.<br />

NordLock Washer<br />

A special type of serrated locking washer is the<br />

NordLock washer. There are always 2 washers needed,<br />

jointly they provide the locking effect.<br />

Dimensions: M6–M130.<br />

When a fastened joint is tightened, the serration<br />

of the two lock washers will line up. If the screw is<br />

subjected to vibration and as a result wants to come<br />

loose, the washer will rotate slightly. Since, however<br />

the serration angle is larger than the thread helix<br />

angle , the loosening of the screw is reliably prevented<br />

through the “increase in washer thickness” of the double<br />

washer.<br />

NordLock washers provide excellent locking against<br />

spontaneous loosening. Nevertheless, there are a few<br />

points to be considered:<br />

One must always use 2 lock washers. Lightly glued<br />

double washers are available. However, they must be<br />

installed separately when reassembled.<br />

If the lock washers are packed individually, meaning<br />

not glued together, there is always the risk that only one<br />

washer is assembled. Another problem is that they may<br />

be assembled facing the wrong direction.<br />

The lock washers lock only against rotational<br />

loosening and not against relaxation of the joint. Also,<br />

they don’t stop an already loosened joint from baking-off<br />

and separating.<br />

The lined-up teeth are not completely closed, causing<br />

a capillary effect and as a result crevice corrosion.<br />

The corroded serrated surfaces won’t slide as easy as<br />

new ones, thus impairing the locking effect.<br />

To assure the washer slides in the serrated interfaces<br />

of the two washers, the washer should not slide between<br />

the interfaces of the washer and the bolt’s head, neither<br />

should it slide in the interface of washer and clamped<br />

part.<br />

Therefore, each washer has a ribbed surface, which<br />

must dig into the bearing area of the bolt as well as the<br />

clamped parts. If the bolt or the clamp parts are too hard<br />

this cannot happen.<br />

Material: Alloy steel, hardness 465HV (46 HRC)<br />

CONTINUED ON PAGE 160