SPRING 2024

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Distributor's Link Magazine Spring 2024 / Vol 47 No 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

160<br />

THE DISTRIBUTOR’S LINK<br />

BRUNO MARBACHER LOCKING FEATURES TO PREVENT ROTATIONAL LOOSENING from page 140<br />

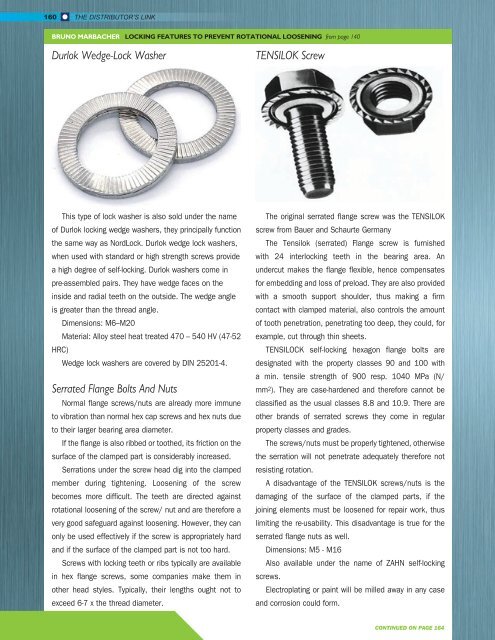

Durlok Wedge-Lock Washer<br />

TENSILOK Screw<br />

This type of lock washer is also sold under the name<br />

of Durlok locking wedge washers, they principally function<br />

the same way as NordLock. Durlok wedge lock washers,<br />

when used with standard or high strength screws provide<br />

a high degree of self-locking. Durlok washers come in<br />

pre-assembled pairs. They have wedge faces on the<br />

inside and radial teeth on the outside. The wedge angle<br />

is greater than the thread angle.<br />

Dimensions: M6–M20<br />

Material: Alloy steel heat treated 470 – 540 HV (47-52<br />

HRC)<br />

Wedge lock washers are covered by DIN 25201-4.<br />

Serrated Flange Bolts And Nuts<br />

Normal flange screws/nuts are already more immune<br />

to vibration than normal hex cap screws and hex nuts due<br />

to their larger bearing area diameter.<br />

If the flange is also ribbed or toothed, its friction on the<br />

surface of the clamped part is considerably increased.<br />

Serrations under the screw head dig into the clamped<br />

member during tightening. Loosening of the screw<br />

becomes more difficult. The teeth are directed against<br />

rotational loosening of the screw/ nut and are therefore a<br />

very good safeguard against loosening. However, they can<br />

only be used effectively if the screw is appropriately hard<br />

and if the surface of the clamped part is not too hard.<br />

Screws with locking teeth or ribs typically are available<br />

in hex flange screws, some companies make them in<br />

other head styles. Typically, their lengths ought not to<br />

exceed 6-7 x the thread diameter.<br />

The original serrated flange screw was the TENSILOK<br />

screw from Bauer and Schaurte Germany<br />

The Tensilok (serrated) Flange screw is furnished<br />

with 24 interlocking teeth in the bearing area. An<br />

undercut makes the flange flexible, hence compensates<br />

for embedding and loss of preload. They are also provided<br />

with a smooth support shoulder, thus making a firm<br />

contact with clamped material, also controls the amount<br />

of tooth penetration, penetrating too deep, they could, for<br />

example, cut through thin sheets.<br />

TENSILOCK self-locking hexagon flange bolts are<br />

designated with the property classes 90 and 100 with<br />

a min. tensile strength of 900 resp. 1040 MPa (N/<br />

mm 2 ). They are case-hardened and therefore cannot be<br />

classified as the usual classes 8.8 and 10.9. There are<br />

other brands of serrated screws they come in regular<br />

property classes and grades.<br />

The screws/nuts must be properly tightened, otherwise<br />

the serration will not penetrate adequately therefore not<br />

resisting rotation.<br />

A disadvantage of the TENSILOK screws/nuts is the<br />

damaging of the surface of the clamped parts, if the<br />

joining elements must be loosened for repair work, thus<br />

limiting the re-usability. This disadvantage is true for the<br />

serrated flange nuts as well.<br />

Dimensions: M5 - M16<br />

Also available under the name of ZAHN self-locking<br />

screws.<br />

Electroplating or paint will be milled away in any case<br />

and corrosion could form.<br />

CONTINUED ON PAGE 164