APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OUTPUT (LBS/24HRS)<br />

8000<br />

6000<br />

4000<br />

2000<br />

4 THRUFLO<br />

UNITS<br />

3 THRUFLO<br />

UNITS<br />

TYPE ‘C2’ 2-TRUCK<br />

EXTRUDED MATERIAL<br />

TYPE ‘C2’ 2-TRUCK<br />

FILTER CAKE<br />

2 THRUFLO<br />

UNITS<br />

1 THRUFLO<br />

UNIT<br />

TYPE No. 2<br />

2-TRUCK<br />

FILTER CAKE<br />

0 0 5 10 15 20 25 30<br />

NUMBER OF TWO-TRUCK UNITS<br />

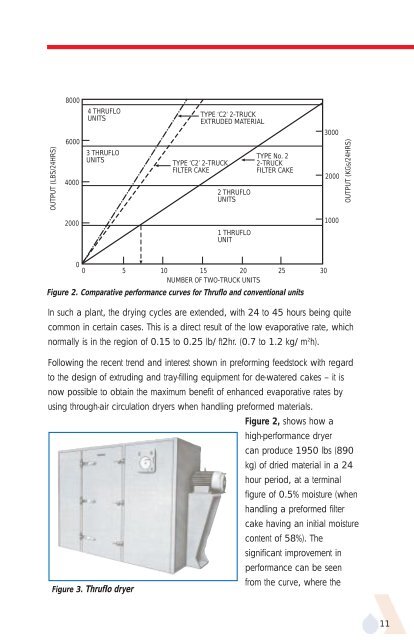

Figure 2. Comparative performance curves for Thruflo and conventional units<br />

In such a plant, the drying cycles are extended, with 24 to 45 hours being quite<br />

common in certain cases. This is a direct result of the low evaporative rate, which<br />

normally is in the region of 0.15 to 0.25 lb/ft2hr. (0.7 to 1.2 kg/m2h). Following the recent trend and interest shown in preforming feedstock with regard<br />

to the design of extruding and tray-filling equipment for de-watered cakes – it is<br />

now possible to obtain the maximum benefit of enhanced evaporative rates by<br />

using through-air circulation dryers when handling preformed materials.<br />

Figure 2, shows how a<br />

high-performance dryer<br />

can produce 1950 lbs (890<br />

kg) of dried material in a 24<br />

hour period, at a terminal<br />

figure of 0.5% moisture (when<br />

handling a preformed filter<br />

cake having an initial moisture<br />

content of 58%). The<br />

significant improvement in<br />

performance can be seen<br />

from the curve, where the<br />

Figure 3. Thruflo dryer<br />

3000<br />

2000<br />

1000<br />

OUTPUT (KGs/24HRS)<br />

11