APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20<br />

material comes into<br />

contact with the hot<br />

gases and, as a result,<br />

higher evaporative rates<br />

can be achieved than<br />

when using countercurrent<br />

flow.<br />

In addition, many<br />

thermo-sensitive materials<br />

can be dried<br />

successfully by this<br />

method. Such an<br />

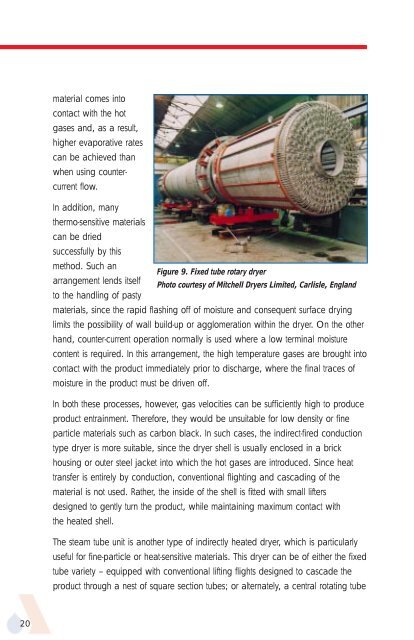

Figure 9. Fixed tube rotary dryer<br />

arrangement lends itself<br />

Photo courtesy of Mitchell <strong>Dryer</strong>s Limited, Carlisle, England<br />

to the handling of pasty<br />

materials, since the rapid flashing off of moisture and consequent surface drying<br />

limits the possibility of wall build-up or agglomeration within the dryer. On the other<br />

hand, counter-current operation normally is used where a low terminal moisture<br />

content is required. In this arrangement, the high temperature gases are brought into<br />

contact with the product immediately prior to discharge, where the final traces of<br />

moisture in the product must be driven off.<br />

In both these processes, however, gas velocities can be sufficiently high to produce<br />

product entrainment. Therefore, they would be unsuitable for low density or fine<br />

particle materials such as carbon black. In such cases, the indirect-fired conduction<br />

type dryer is more suitable, since the dryer shell is usually enclosed in a brick<br />

housing or outer steel jacket into which the hot gases are introduced. Since heat<br />

transfer is entirely by conduction, conventional flighting and cascading of the<br />

material is not used. Rather, the inside of the shell is fitted with small lifters<br />

designed to gently turn the product, while maintaining maximum contact with<br />

the heated shell.<br />

The steam tube unit is another type of indirectly heated dryer, which is particularly<br />

useful for fine-particle or heat-sensitive materials. This dryer can be of either the fixed<br />

tube variety – equipped with conventional lifting flights designed to cascade the<br />

product through a nest of square section tubes; or alternately, a central rotating tube