APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

24<br />

circulation. Alternatively, and where there is limited floor space or a possible<br />

need for long residence time, multi-pass units are used with the conveyors<br />

mounted one above the other. In similar circumstances, another special type<br />

of multi-deck dryer can be used which employs a system of tilting trays so that<br />

the product is supported on both the normal working and the inside of the return<br />

run of the conveyor band. This arrangement considerably increases the residence<br />

time within the dryer and is particularly useful where the product has poor<br />

diffusion characteristics.<br />

The method of airflow employed on these dryers is either vertically downward<br />

through the material and the supporting band or alternatively upward. Sometimes<br />

a combination of the two may be dictated by the nature of the wet feed. It<br />

occasionally happens that extruded materials have a tendency to coalesce<br />

when deposited on the band, in which case one or more sections at the wet end<br />

of the dryer may be arranged for upward air flow to reduce the effect. Wherever<br />

possible, through-air circulation is used as opposed to transverse air flow. This<br />

results in greatly increased evaporative rates as, may be seen from Table 1.<br />

An illustration of the relatively high performance of a band dryer operating on this<br />

system, as compared with a unit having transverse air flow, can be cited in a case<br />

involving the processing of a 70% moisture content filter cake. When this material<br />

is dried in a conventional unit, the cycle time is in the region of 28 hours. This<br />

is reduced to 55 minutes<br />

in the through-circulation<br />

band dryer, largely<br />

as a result of using<br />

an extruder/preformer<br />

designed to produce a<br />

dimensionally stable bed<br />

of sufficient porosity to<br />

permit air circulation<br />

through the feed.<br />

In view of this, transverse<br />

air flow is usually used<br />

only where the type<br />

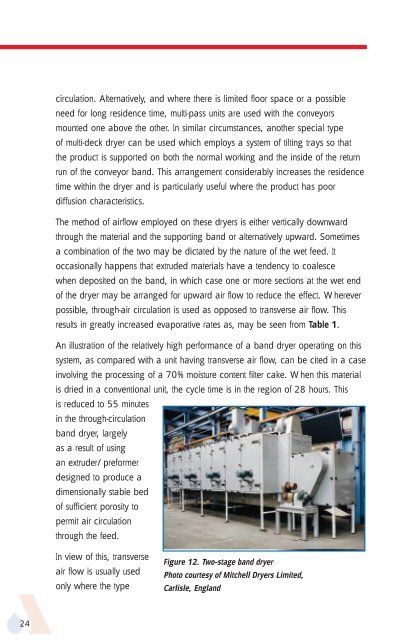

Figure 12. Two-stage band dryer<br />

Photo courtesy of Mitchell <strong>Dryer</strong>s Limited,<br />

Carlisle, England