APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

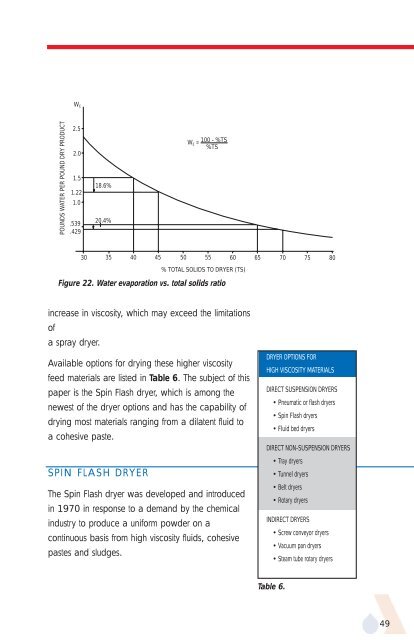

POUNDS WATER PER POUND DRY PRODUCT<br />

W E<br />

2.5<br />

2.0<br />

1.5<br />

1.22<br />

1.0<br />

.539<br />

.429<br />

18.6%<br />

20.4%<br />

increase in viscosity, which may exceed the limitations<br />

of<br />

a spray dryer.<br />

Available options for drying these higher viscosity<br />

feed materials are listed in Table 6. The subject of this<br />

paper is the Spin Flash dryer, which is among the<br />

newest of the dryer options and has the capability of<br />

drying most materials ranging from a dilatent fluid to<br />

a cohesive paste.<br />

SPIN FLASH DRYER<br />

WE = 100 - %TS<br />

%TS<br />

30 35 40 45 50 55 60 65 70 75 80<br />

% TOTAL SOLIDS TO DRYER (TS)<br />

Figure 22. Water evaporation vs. total solids ratio<br />

The Spin Flash dryer was developed and introduced<br />

in 1970 in response to a demand by the chemical<br />

industry to produce a uniform powder on a<br />

continuous basis from high viscosity fluids, cohesive<br />

pastes and sludges.<br />

DRYER OPTIONS FOR<br />

HIGH VISCOSITY MATERIALS<br />

DIRECT SUSPENSION DRYERS<br />

• Pneumatic or flash dryers<br />

• Spin Flash dryers<br />

• Fluid bed dryers<br />

DIRECT NON-SUSPENSION DRYERS<br />

• Tray dryers<br />

• Tunnel dryers<br />

• Belt dryers<br />

• Rotary dryers<br />

INDIRECT DRYERS<br />

• Screw conveyor dryers<br />

• Vacuum pan dryers<br />

• Steam tube rotary dryers<br />

Table 6.<br />

49