APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

50<br />

PROCESS DESCRIPTION<br />

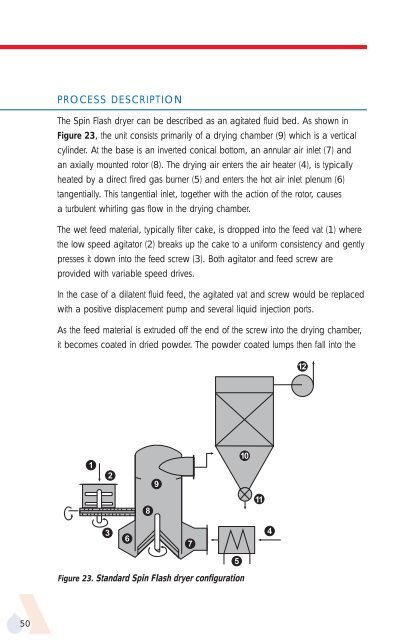

The Spin Flash dryer can be described as an agitated fluid bed. As shown in<br />

Figure 23, the unit consists primarily of a drying chamber (9) which is a vertical<br />

cylinder. At the base is an inverted conical bottom, an annular air inlet (7) and<br />

an axially mounted rotor (8). The drying air enters the air heater (4), is typically<br />

heated by a direct fired gas burner (5) and enters the hot air inlet plenum (6)<br />

tangentially. This tangential inlet, together with the action of the rotor, causes<br />

a turbulent whirling gas flow in the drying chamber.<br />

The wet feed material, typically filter cake, is dropped into the feed vat (1) where<br />

the low speed agitator (2) breaks up the cake to a uniform consistency and gently<br />

presses it down into the feed screw (3). Both agitator and feed screw are<br />

provided with variable speed drives.<br />

In the case of a dilatent fluid feed, the agitated vat and screw would be replaced<br />

with a positive displacement pump and several liquid injection ports.<br />

As the feed material is extruded off the end of the screw into the drying chamber,<br />

it becomes coated in dried powder. The powder coated lumps then fall into the<br />

1<br />

3<br />

2<br />

6<br />

8<br />

Figure 23. Standard Spin Flash dryer configuration<br />

9<br />

7<br />

5<br />

10<br />

11<br />

4<br />

12