APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

POWDER TYPE<br />

D R Y E R S<br />

Fine<br />

Freeflow<br />

Dustless<br />

Granular<br />

Wettable<br />

Agglom<br />

Coated<br />

Lump<br />

SELECTION, SIZING, COSTS<br />

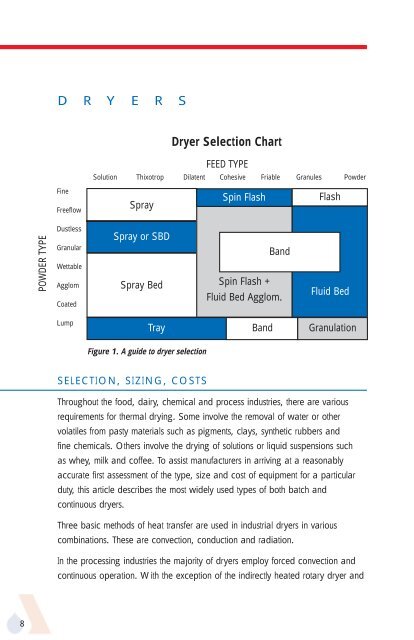

<strong>Dryer</strong> Selection Chart<br />

FEED TYPE<br />

Solution Thixotrop Dilatent Cohesive Friable Granules Powder<br />

Spray<br />

Spray or SBD<br />

Spray Bed<br />

Figure 1. A guide to dryer selection<br />

Spin Flash Flash<br />

Band<br />

Spin Flash +<br />

Fluid Bed Agglom.<br />

Fluid Bed<br />

Tray Band Granulation<br />

Throughout the food, dairy, chemical and process industries, there are various<br />

requirements for thermal drying. Some involve the removal of water or other<br />

volatiles from pasty materials such as pigments, clays, synthetic rubbers and<br />

fine chemicals. Others involve the drying of solutions or liquid suspensions such<br />

as whey, milk and coffee. To assist manufacturers in arriving at a reasonably<br />

accurate first assessment of the type, size and cost of equipment for a particular<br />

duty, this article describes the most widely used types of both batch and<br />

continuous dryers.<br />

Three basic methods of heat transfer are used in industrial dryers in various<br />

combinations. These are convection, conduction and radiation.<br />

In the processing industries the majority of dryers employ forced convection and<br />

continuous operation. With the exception of the indirectly heated rotary dryer and