APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FLOW RATE<br />

The flow rate of liquid<br />

into the spray dryer is<br />

used to control the dryer<br />

outlet temperature and<br />

hold it at a given value<br />

to keep a controlled<br />

powder moisture.<br />

If a certain product can<br />

be dried at a higher inlet<br />

temperature, then the flow<br />

rate will be higher to keep<br />

0 100 200 300 mm<br />

the outlet temperature<br />

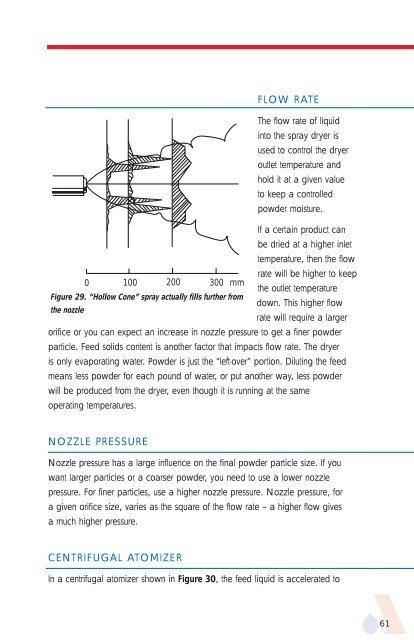

Figure 29. “Hollow Cone” spray actually fills further from<br />

down. This higher flow<br />

the nozzle<br />

rate will require a larger<br />

orifice or you can expect an increase in nozzle pressure to get a finer powder<br />

particle. Feed solids content is another factor that impacts flow rate. The dryer<br />

is only evaporating water. Powder is just the “left-over” portion. Diluting the feed<br />

means less powder for each pound of water, or put another way, less powder<br />

will be produced from the dryer, even though it is running at the same<br />

operating temperatures.<br />

NOZZLE PRESSURE<br />

Nozzle pressure has a large influence on the final powder particle size. If you<br />

want larger particles or a coarser powder, you need to use a lower nozzle<br />

pressure. For finer particles, use a higher nozzle pressure. Nozzle pressure, for<br />

a given orifice size, varies as the square of the flow rate – a higher flow gives<br />

a much higher pressure.<br />

CENTRIFUGAL ATOMIZER<br />

In a centrifugal atomizer shown in Figure 30, the feed liquid is accelerated to<br />

61