APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

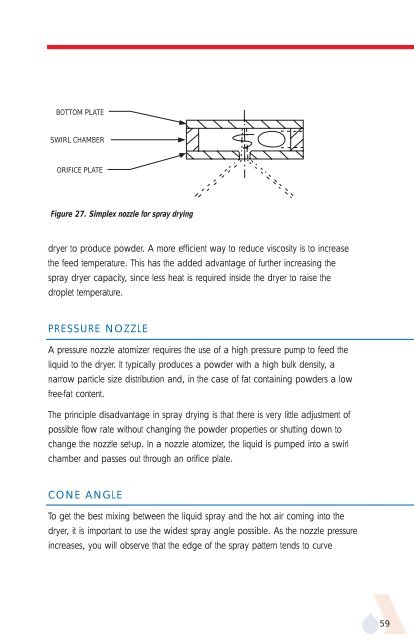

BOTTOM PLATE<br />

SWIRL CHAMBER<br />

ORIFICE PLATE<br />

Figure 27. Simplex nozzle for spray drying<br />

dryer to produce powder. A more efficient way to reduce viscosity is to increase<br />

the feed temperature. This has the added advantage of further increasing the<br />

spray dryer capacity, since less heat is required inside the dryer to raise the<br />

droplet temperature.<br />

PRESSURE NOZZLE<br />

A pressure nozzle atomizer requires the use of a high pressure pump to feed the<br />

liquid to the dryer. It typically produces a powder with a high bulk density, a<br />

narrow particle size distribution and, in the case of fat containing powders a low<br />

free-fat content.<br />

The principle disadvantage in spray drying is that there is very little adjustment of<br />

possible flow rate without changing the powder properties or shutting down to<br />

change the nozzle set-up. In a nozzle atomizer, the liquid is pumped into a swirl<br />

chamber and passes out through an orifice plate.<br />

CONE ANGLE<br />

To get the best mixing between the liquid spray and the hot air coming into the<br />

dryer, it is important to use the widest spray angle possible. As the nozzle pressure<br />

increases, you will observe that the edge of the spray pattern tends to curve<br />

59