APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

32<br />

DRYER FEED MOISTURE CONTENT (% W.W.B.)<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

B<br />

A<br />

material can be increased from 50% to<br />

60% by evaporation, the amount of<br />

water to be evaporated in the spray<br />

dryer is reduced by 33%. A similar<br />

example is shown in Table 2. In this<br />

case the surplus water is being removed<br />

by filtration, and the resulting cake flash<br />

dried. This results in a smaller and less<br />

expensive dryer because evaporation is<br />

far more thermally efficient than drying.<br />

For example, a double effect<br />

evaporator for kaolin will require only<br />

1/3 the energy per unit of evaporation<br />

than the dryer. The pre-concentration<br />

will save approximately 15 million<br />

BTU/h (3.8 million Kcal/h).<br />

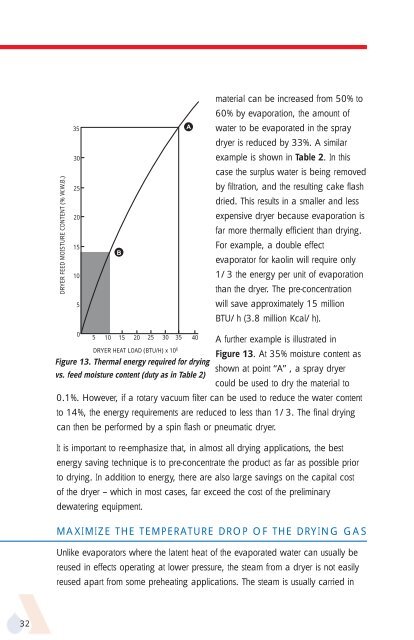

A further example is illustrated in<br />

DRYER HEAT LOAD (BTU/H) x 10<br />

Figure 13. At 35% moisture content as<br />

shown at point “A” , a spray dryer<br />

could be used to dry the material to<br />

0.1%. However, if a rotary vacuum filter can be used to reduce the water content<br />

to 14%, the energy requirements are reduced to less than 1/3. The final drying<br />

can then be performed by a spin flash or pneumatic dryer.<br />

6<br />

5 10 15 20 25 30 35 40<br />

Figure 13. Thermal energy required for drying<br />

vs. feed moisture content (duty as in Table 2)<br />

It is important to re-emphasize that, in almost all drying applications, the best<br />

energy saving technique is to pre-concentrate the product as far as possible prior<br />

to drying. In addition to energy, there are also large savings on the capital cost<br />

of the dryer – which in most cases, far exceed the cost of the preliminary<br />

dewatering equipment.<br />

MAXIMIZE THE TEMPERATURE DROP OF THE DRYING GAS<br />

Unlike evaporators where the latent heat of the evaporated water can usually be<br />

reused in effects operating at lower pressure, the steam from a dryer is not easily<br />

reused apart from some preheating applications. The steam is usually carried in