APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

■ Utilizing direct heat wherever possible.<br />

■ Reducing radiation and convection heat loss by means of efficient<br />

thermal insulation.<br />

The most important of the above is to minimize the water content of the feed<br />

by pretreatment with other techniques. Mechanical separation processes such<br />

as settling, centrifuging, filtration, reverse osmosis, etc., are far more energy<br />

efficient than thermal processes. When mechanical separation is not possible,<br />

evaporation should be considered. Although evaporation is a thermal process, the<br />

thermal efficiency of water removal is many times that of a dryer. In a large system,<br />

it is possible to evaporate 7 or 8 mass units of water for 1 mass unit of steam<br />

supply. Mechanical recompression evaporation can be even more energy efficient.<br />

A typical dryer does not even evaporate 1 mass unit per 1 mass unit of steam.<br />

MINIMIZE WATER CONTENT OF THE FEED<br />

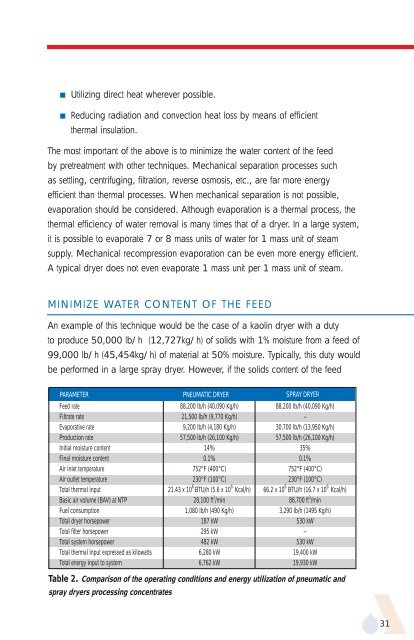

An example of this technique would be the case of a kaolin dryer with a duty<br />

to produce 50,000 lb/h (12,727kg/h) of solids with 1% moisture from a feed of<br />

99,000 lb/h (45,454kg/h) of material at 50% moisture. Typically, this duty would<br />

be performed in a large spray dryer. However, if the solids content of the feed<br />

PARAMETER PNEUMATIC DRYER SPRAY DRYER<br />

Feed rate 88,200 lb/h (40,090 Kg/h) 88,200 lb/h (40,090 Kg/h)<br />

Filtrate rate 21,500 lb/h (9,770 Kg/h) –<br />

Evaporative rate 9,200 lb/h (4,180 Kg/h) 30,700 lb/h (13,950 Kg/h)<br />

Production rate 57,500 lb/h (26,100 Kg/h) 57,500 lb/h (26,100 Kg/h)<br />

Initial moisture content 14% 35%<br />

Final moisture content 0.1% 0.1%<br />

Air inlet temperature 752°F (400°C) 752°F (400°C)<br />

Air outlet temperature 230°F (100°C) 230°F (100°C)<br />

Total thermal input 21.43 x 10 6 BTU/h (5.6 x 10 6 Kcal/h) 66.2 x 10 6 BTU/h (16.7 x 10 6 Kcal/h)<br />

Basic air volume (BAV) at NTP 28,100 ft 3 /min 86,700 ft 3 /min<br />

Fuel consumption 1,080 lb/h (490 Kg/h) 3,290 lb/h (1495 Kg/h)<br />

Total dryer horsepower 187 kW 530 kW<br />

Total filter horsepower 295 kW –<br />

Total system horsepower 482 kW 530 kW<br />

Total thermal input expressed as kilowatts 6,280 kW 19,400 kW<br />

Total energy input to system 6,762 kW 19,930 kW<br />

Table 2. Comparison of the operating conditions and energy utilization of pneumatic and<br />

spray dryers processing concentrates<br />

31