APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

66<br />

variations, some plants utilize an inlet air dehumidification system.<br />

The ambient air is drawn into the plant through filters to remove dust and airborne<br />

contaminants which could foul the equipment, then across a chilling coil. This coil<br />

is cooled to around 33°F (0.5°C) by a recirculated stream of water and glycol.<br />

The cold coil surface, with the extended fins, cools the air and causes the<br />

ambient moisture to condense on the coil surface. This condensation runs down<br />

the surface of the coils and is collected in a trough at the base from which it runs<br />

to a building drain. The air velocity across the face of the coil is important. Too<br />

high a velocity will prevent the water droplets from clinging to the coil surface,<br />

producing a mist, that will pass downstream to the fan. To reduce the danger<br />

of this, most systems are followed by a demister, comprising either chevrons or<br />

a coarse polymer demisting pad.<br />

OUTLET TEMPERATURE<br />

The spray dryer outlet temperature is controlled by adjusting the feed rate to the<br />

atomizer. This, in turn, is accomplished by adjusting the speed of the feed pump<br />

through a variable frequency drive. As more feed is atomized into the dryer<br />

chamber, it cools the air in the chamber and the outlet temperature goes down. It<br />

is important to note that unless the feed is adequately atomized, the outlet<br />

PRODUCTION RATE<br />

(Kg/hr)<br />

9,000<br />

5,000<br />

2,500<br />

(lbs/hr)<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

0<br />

1 3 5 7 9 11<br />

MONTH<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

INLET AIR<br />

ABSOLUTE HUMIDITY<br />

(g/kg)<br />

PRODUCT 1<br />

PRODUCT 2<br />

PRODUCT 3<br />

PRODUCT 4<br />

PRODUCT 5<br />

PRODUCT 6<br />

ABS. HUMIDITY<br />

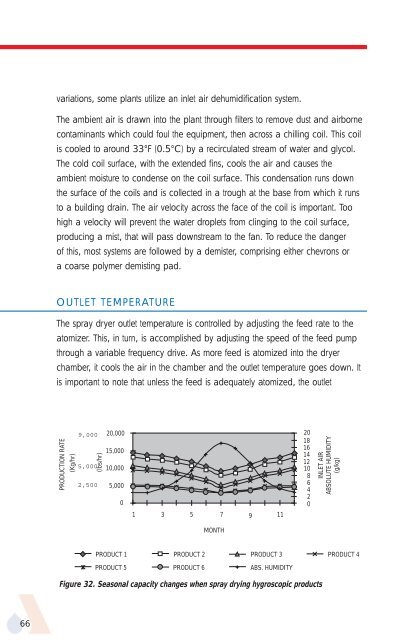

Figure 32. Seasonal capacity changes when spray drying hygroscopic products