APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

APV Dryer Handbook - Umbc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

fluid bed and are kept in<br />

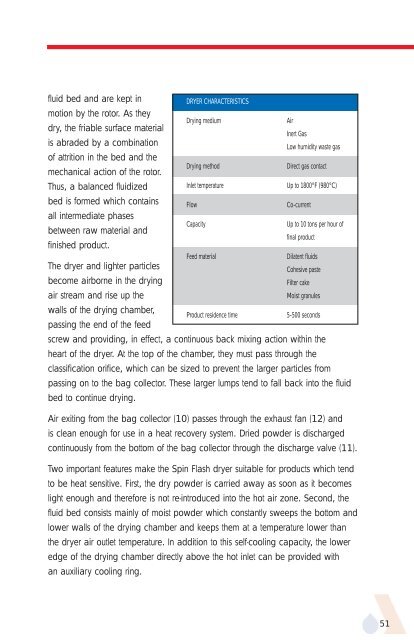

DRYER CHARACTERISTICS<br />

motion by the rotor. As they<br />

dry, the friable surface material<br />

Drying medium Air<br />

Inert Gas<br />

is abraded by a combination<br />

of attrition in the bed and the<br />

Low humidity waste gas<br />

mechanical action of the rotor.<br />

Drying method Direct gas contact<br />

Thus, a balanced fluidized<br />

Inlet temperature Up to 1800°F (980°C)<br />

bed is formed which contains<br />

all intermediate phases<br />

Flow Co-current<br />

between raw material and<br />

finished product.<br />

Capacity Up to 10 tons per hour of<br />

final product<br />

Feed material Dilatent fluids<br />

The dryer and lighter particles<br />

Cohesive paste<br />

become airborne in the drying<br />

Filter cake<br />

air stream and rise up the<br />

Moist granules<br />

walls of the drying chamber,<br />

passing the end of the feed<br />

Product residence time 5-500 seconds<br />

screw and providing, in effect, a continuous back mixing action within the<br />

heart of the dryer. At the top of the chamber, they must pass through the<br />

classification orifice, which can be sized to prevent the larger particles from<br />

passing on to the bag collector. These larger lumps tend to fall back into the fluid<br />

bed to continue drying.<br />

Air exiting from the bag collector (10) passes through the exhaust fan (12) and<br />

is clean enough for use in a heat recovery system. Dried powder is discharged<br />

continuously from the bottom of the bag collector through the discharge valve (11).<br />

Two important features make the Spin Flash dryer suitable for products which tend<br />

to be heat sensitive. First, the dry powder is carried away as soon as it becomes<br />

light enough and therefore is not re-introduced into the hot air zone. Second, the<br />

fluid bed consists mainly of moist powder which constantly sweeps the bottom and<br />

lower walls of the drying chamber and keeps them at a temperature lower than<br />

the dryer air outlet temperature. In addition to this self-cooling capacity, the lower<br />

edge of the drying chamber directly above the hot inlet can be provided with<br />

an auxiliary cooling ring.<br />

51