Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

52 DUALRANGE ® CONTROL VALVE<br />

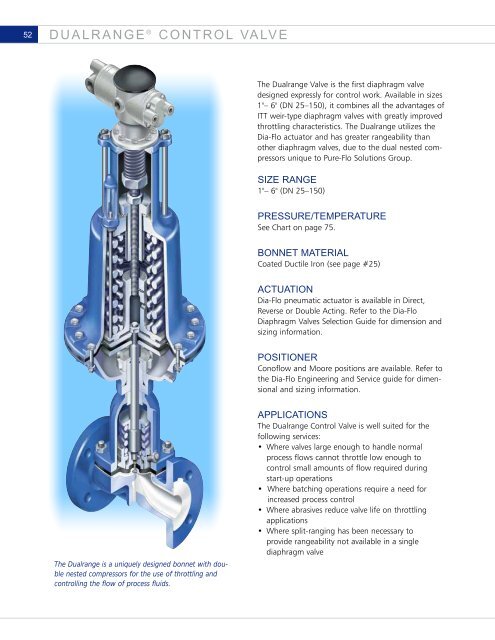

The Dualrange is a uniquely designed bonnet with double<br />

nested compressors for the use of throttling and<br />

controlling the flow of process fluids.<br />

The Dualrange Valve is the first diaphragm valve<br />

designed expressly for control work. Available in sizes<br />

1"– 6" (DN 25–150), it combines all the advantages of<br />

ITT weir-type diaphragm valves with greatly improved<br />

throttling characteristics. The Dualrange utilizes the<br />

Dia-Flo actuator and has greater rangeability than<br />

other diaphragm valves, due to the dual nested compressors<br />

unique to <strong>Pure</strong>-Flo Solutions Group.<br />

SIZE RANGE<br />

1"– 6" (DN 25–150)<br />

PRESSURE/TEMPERATURE<br />

See Chart on page 75.<br />

BONNET MATERIAL<br />

Coated Ductile Iron (see page #25)<br />

ACTUATION<br />

Dia-Flo pneumatic actuator is available in Direct,<br />

Reverse or Double Acting. Refer to the Dia-Flo<br />

Diaphragm Valves Selection Guide for dimension and<br />

sizing information.<br />

POSITIONER<br />

Conoflow and Moore positions are available. Refer to<br />

the Dia-Flo Engineering and Service guide for dimensional<br />

and sizing information.<br />

APPLICATIONS<br />

The Dualrange Control Valve is well suited for the<br />

following services:<br />

• Where valves large enough to handle normal<br />

process flows cannot throttle low enough to<br />

control small amounts of flow required during<br />

start-up operations<br />

• Where batching operations require a need for<br />

increased process control<br />

• Where abrasives reduce valve life on throttling<br />

applications<br />

• Where split-ranging has been necessary to<br />

provide rangeability not available in a single<br />

diaphragm valve