Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

68 STERILE TANK VENT FILTER SHUNT VALVE<br />

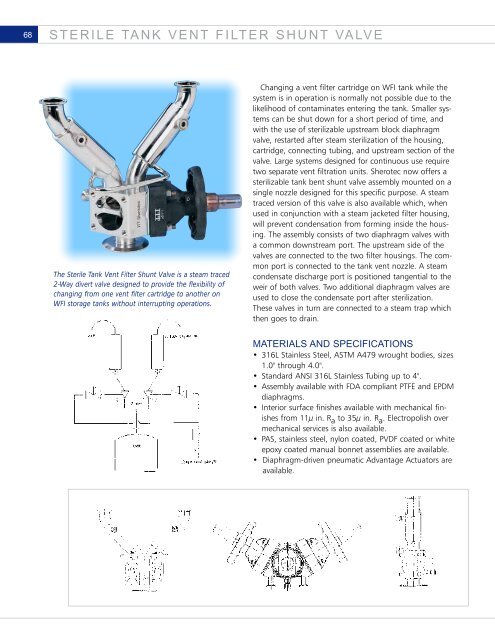

The Sterile Tank Vent Filter Shunt Valve is a steam traced<br />

2-Way divert valve designed to provide the flexibility of<br />

changing from one vent filter cartridge to another on<br />

WFI storage tanks without interrupting operations.<br />

Changing a vent filter cartridge on WFI tank while the<br />

system is in operation is normally not possible due to the<br />

likelihood of contaminates entering the tank. Smaller systems<br />

can be shut down for a short period of time, and<br />

with the use of sterilizable upstream block diaphragm<br />

valve, restarted after steam sterilization of the housing,<br />

cartridge, connecting tubing, and upstream section of the<br />

valve. Large systems designed for continuous use require<br />

two separate vent filtration units. Sherotec now offers a<br />

sterilizable tank bent shunt valve assembly mounted on a<br />

single nozzle designed for this specific purpose. A steam<br />

traced version of this valve is also available which, when<br />

used in conjunction with a steam jacketed filter housing,<br />

will prevent condensation from forming inside the housing.<br />

The assembly consists of two diaphragm valves with<br />

a common downstream port. The upstream side of the<br />

valves are connected to the two filter housings. The common<br />

port is connected to the tank vent nozzle. A steam<br />

condensate discharge port is positioned tangential to the<br />

weir of both valves. Two additional diaphragm valves are<br />

used to close the condensate port after sterilization.<br />

These valves in turn are connected to a steam trap which<br />

then goes to drain.<br />

MATERIALS AND SPECIFICATIONS<br />

• 316L Stainless Steel, ASTM A479 wrought bodies, sizes<br />

1.0" through 4.0".<br />

• Standard ANSI 316L Stainless Tubing up to 4".<br />

• Assembly available with FDA compliant PTFE and EPDM<br />

diaphragms.<br />

• Interior surface finishes available with mechanical finishes<br />

from 11μ in. R a to 35μ in. R a . Electropolish over<br />

mechanical services is also available.<br />

• PAS, stainless steel, nylon coated, PVDF coated or white<br />

epoxy coated manual bonnet assemblies are available.<br />

• Diaphragm-driven pneumatic Advantage Actuators are<br />

available.