You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PURE-FLO ® DIVERT VALVES<br />

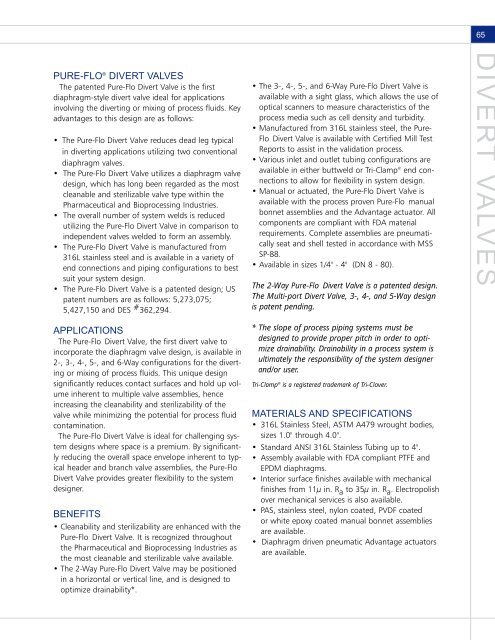

The patented <strong>Pure</strong>-Flo Divert Valve is the first<br />

diaphragm-style divert valve ideal for applications<br />

involving the diverting or mixing of process fluids. Key<br />

advantages to this design are as follows:<br />

• The <strong>Pure</strong>-Flo Divert Valve reduces dead leg typical<br />

in diverting applications utilizing two conventional<br />

diaphragm valves.<br />

• The <strong>Pure</strong>-Flo Divert Valve utilizes a diaphragm valve<br />

design, which has long been regarded as the most<br />

cleanable and sterilizable valve type within the<br />

Pharmaceutical and Bioprocessing Industries.<br />

• The overall number of system welds is reduced<br />

utilizing the <strong>Pure</strong>-Flo Divert Valve in comparison to<br />

independent valves welded to form an assembly.<br />

• The <strong>Pure</strong>-Flo Divert Valve is manufactured from<br />

316L stainless steel and is available in a variety of<br />

end connections and piping configurations to best<br />

suit your system design.<br />

• The <strong>Pure</strong>-Flo Divert Valve is a patented design; US<br />

patent numbers are as follows: 5,273,075;<br />

5,427,150 and DES # 362,294.<br />

APPLICATIONS<br />

The <strong>Pure</strong>-Flo Divert Valve, the first divert valve to<br />

incorporate the diaphragm valve design, is available in<br />

2-, 3-, 4-, 5-, and 6-Way configurations for the diverting<br />

or mixing of process fluids. This unique design<br />

significantly reduces contact surfaces and hold up volume<br />

inherent to multiple valve assemblies, hence<br />

increasing the cleanability and sterilizability of the<br />

valve while minimizing the potential for process fluid<br />

contamination.<br />

The <strong>Pure</strong>-Flo Divert Valve is ideal for challenging system<br />

designs where space is a premium. By significantly<br />

reducing the overall space envelope inherent to typical<br />

header and branch valve assemblies, the <strong>Pure</strong>-Flo<br />

Divert Valve provides greater flexibility to the system<br />

designer.<br />

BENEFITS<br />

• Cleanability and sterilizability are enhanced with the<br />

<strong>Pure</strong>-Flo Divert Valve. It is recognized throughout<br />

the Pharmaceutical and Bioprocessing Industries as<br />

the most cleanable and sterilizable valve available.<br />

• The 2-Way <strong>Pure</strong>-Flo Divert Valve may be positioned<br />

in a horizontal or vertical line, and is designed to<br />

optimize drainability*.<br />

• The 3-, 4-, 5-, and 6-Way <strong>Pure</strong>-Flo Divert Valve is<br />

available with a sight glass, which allows the use of<br />

optical scanners to measure characteristics of the<br />

process media such as cell density and turbidity.<br />

• Manufactured from 316L stainless steel, the <strong>Pure</strong>-<br />

Flo Divert Valve is available with Certified Mill Test<br />

Reports to assist in the validation process.<br />

• Various inlet and outlet tubing configurations are<br />

available in either buttweld or Tri-Clamp ® end connections<br />

to allow for flexibility in system design.<br />

• Manual or actuated, the <strong>Pure</strong>-Flo Divert Valve is<br />

available with the process proven <strong>Pure</strong>-Flo manual<br />

bonnet assemblies and the Advantage actuator. All<br />

components are compliant with FDA material<br />

requirements. Complete assemblies are pneumatically<br />

seat and shell tested in accordance with MSS<br />

SP-88.<br />

• Available in sizes 1/4" - 4" (DN 8 - 80).<br />

The 2-Way <strong>Pure</strong>-Flo Divert Valve is a patented design.<br />

The Multi-port Divert Valve, 3-, 4-, and 5-Way design<br />

is patent pending.<br />

* The slope of process piping systems must be<br />

designed to provide proper pitch in order to optimize<br />

drainability. Drainability in a process system is<br />

ultimately the responsibility of the system designer<br />

and/or user.<br />

Tri-Clamp ® is a registered trademark of Tri-Clover.<br />

MATERIALS AND SPECIFICATIONS<br />

• 316L Stainless Steel, ASTM A479 wrought bodies,<br />

sizes 1.0" through 4.0".<br />

• Standard ANSI 316L Stainless Tubing up to 4".<br />

• Assembly available with FDA compliant PTFE and<br />

EPDM diaphragms.<br />

• Interior surface finishes available with mechanical<br />

finishes from 11μ in. Ra to 35μ in. Ra . Electropolish<br />

over mechanical services is also available.<br />

• PAS, stainless steel, nylon coated, PVDF coated<br />

or white epoxy coated manual bonnet assemblies<br />

are available.<br />

• Diaphragm driven pneumatic Advantage actuators<br />

are available.<br />

65<br />

DIVERT VALVES