You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

“Our customers have been more than pleased with the performance of the <strong>Pure</strong>-Flo Tank Bottom Diaphragm Valve. Several<br />

customers have contracted us to retrofit their bioreactors with the <strong>Pure</strong>-Flo Valve. In continual dealings and communications<br />

with ITT, the service has been first class. We would definitely recommend ITT to any of our customers and feel that<br />

the ITT design only enhances our workmanship and installation in presenting a desirable package to our customers.”<br />

Fred R. Schaefer, Jr. , Mechanical Superintendent, The Whiting-Turner Contracting Company, Baltimore, Maryland<br />

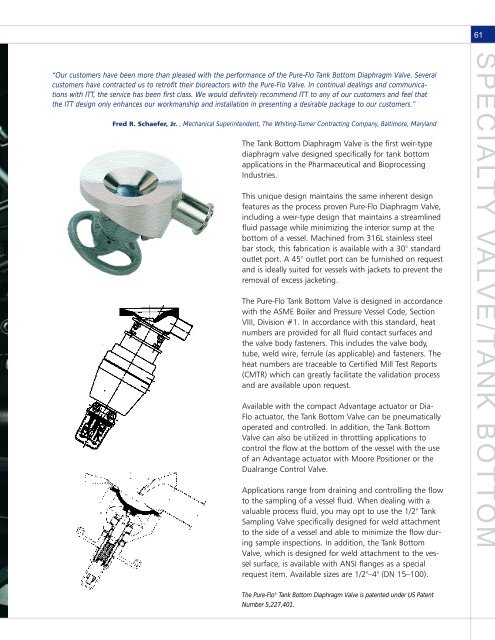

The Tank Bottom Diaphragm Valve is the first weir-type<br />

diaphragm valve designed specifically for tank bottom<br />

applications in the Pharmaceutical and Bioprocessing<br />

Industries.<br />

This unique design maintains the same inherent design<br />

features as the process proven <strong>Pure</strong>-Flo Diaphragm Valve,<br />

including a weir-type design that maintains a streamlined<br />

fluid passage while minimizing the interior sump at the<br />

bottom of a vessel. Machined from 316L stainless steel<br />

bar stock, this fabrication is available with a 30° standard<br />

outlet port. A 45° outlet port can be furnished on request<br />

and is ideally suited for vessels with jackets to prevent the<br />

removal of excess jacketing.<br />

The <strong>Pure</strong>-Flo Tank Bottom Valve is designed in accordance<br />

with the ASME Boiler and Pressure Vessel Code, Section<br />

VIII, Division #1. In accordance with this standard, heat<br />

numbers are provided for all fluid contact surfaces and<br />

the valve body fasteners. This includes the valve body,<br />

tube, weld wire, ferrule (as applicable) and fasteners. The<br />

heat numbers are traceable to Certified Mill Test Reports<br />

(CMTR) which can greatly facilitate the validation process<br />

and are available upon request.<br />

Available with the compact Advantage actuator or Dia-<br />

Flo actuator, the Tank Bottom Valve can be pneumatically<br />

operated and controlled. In addition, the Tank Bottom<br />

Valve can also be utilized in throttling applications to<br />

control the flow at the bottom of the vessel with the use<br />

of an Advantage actuator with Moore Positioner or the<br />

Dualrange Control Valve.<br />

Applications range from draining and controlling the flow<br />

to the sampling of a vessel fluid. When dealing with a<br />

valuable process fluid, you may opt to use the 1/2" Tank<br />

Sampling Valve specifically designed for weld attachment<br />

to the side of a vessel and able to minimize the flow during<br />

sample inspections. In addition, the Tank Bottom<br />

Valve, which is designed for weld attachment to the vessel<br />

surface, is available with ANSI flanges as a special<br />

request item. Available sizes are 1/2"–4" (DN 15–100).<br />

The <strong>Pure</strong>-Flo ® Tank Bottom Diaphragm Valve is patented under US Patent<br />

Number 5,227,401.<br />

61<br />

SPECIALTY VALVE/TANK BOTTOM