Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Page 26 CONTINENTAL L-HEAD ENGINE MANUAL<br />

7. LUBRICATE POWER TAKE OFF<br />

Using grease gun, lubricate the clutch throwout<br />

bearing and output shaft bearing with approved<br />

ball bearing grease.<br />

Operations requiring frequent de-clutching<br />

should be lubricated daily.<br />

Figure 5!<br />

TORQUE DOWN CYLINDER HEAD TO<br />

SPECIFICATIONS IN MANUAL.<br />

ADJUST IDLE MIXTURE AND IDLE SPEED TO<br />

400-600 R. P. M. REPEAT AGAIN AT THE<br />

END OF 500 HOURS<br />

REPEAT DALLY AND SO-HOUR SCHEDULES<br />

Follow previous instructions.<br />

2e CLEAN EXTERIOR OF ENGINE<br />

Use steam if available,<br />

commercial engine cleaner<br />

engine.<br />

otherwise any good<br />

to wash down the<br />

Figure 52<br />

3. CHECK GOVERNOR CONTROL<br />

Clean and lubricate all governor linkage to insure<br />

free operation of governor. Free-up any joints<br />

that may be binding or rods or levers that may be<br />

twisted. Check for full throttle opening.<br />

Figure 53<br />

4. CLEAN SPARK PLUGS<br />

Clean depressions around plugs before removing<br />

them -- then clean and re-set point gap to<br />

.025 on standard plugs and .035 on resistor plugs.<br />

Install spark plugs (18mm) and tighten<br />

35 ft. Ibs. torque.<br />

Figure 54<br />

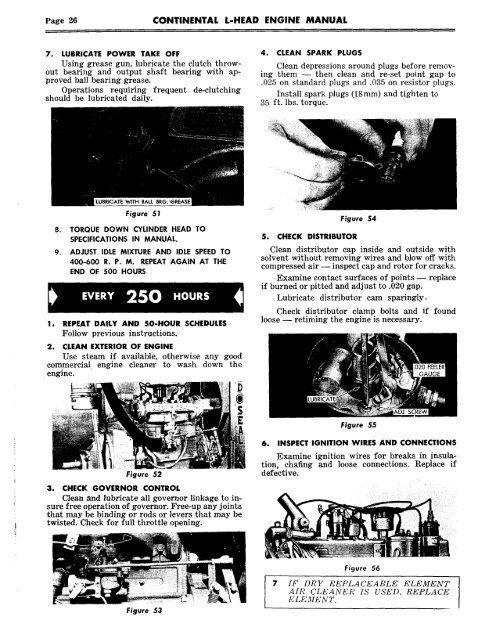

5. CHECK DISTRIBUTOR<br />

Clean distributor cap inside and outside with<br />

solvent without removing wires and blow off with<br />

compressed air -- inspect cap and rotor for cracks.<br />

Examine contact surfaces of points -- replace<br />

if burned or pitted and adjust to .020 gap.<br />

Lubricate distributor cam sparingly.<br />

Check distributor clamp bolts and if found<br />

loose -- retiming the engine is necessary.<br />

Figure 55<br />

6. INSPECT IGNITION WIRES AND CONNECTIONS<br />

Examine ignition wires for breaks in insulation,<br />

chafing and loose connections. Replace if<br />

defective.<br />

7<br />

Figure 56<br />

IF DRY REPLACEABLE ELEMENT<br />

AIR CLEANER IS USED, REPLACE<br />

ELEMENT.