Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 46 CONTINENTAL L-HEAD ENGINE MANUAL<br />

If the points are servicable, they should be<br />

dressed down with a fine-cut stone or point file.<br />

The file must be clean and sharp -- never use<br />

emery cloth to clean contact points.<br />

After filing, check the point gap and reset to<br />

.020 -- the breaker arm must be resting on the<br />

high point of the cam during this operation.<br />

When replacing points, make sure they are<br />

aligned and that they make full contact. Bend the<br />

stationary arm to obtain proper alignment -- do<br />

not bend the breaker arm.<br />

4 -- Lubrication -- is required at the shaft, advance<br />

mechanism, breaker cam and pivot. The<br />

shaft may be either oil or grease cup lubricated<br />

and should be given attention every oil change.<br />

Make sure the breaker arm moves freely on its<br />

hinge and apply a drop of light oil. A trace of<br />

ball bearing lubricant such as Mobilgrease Special<br />

(with Moly) should be used sparingly on the<br />

breaker cam unless lubricated by a felt wick with<br />

a few drops of oil.<br />

CAUTION:<br />

AVOID EXCESSIVE LUBRICATION -- AS<br />

THE EXCESS MAY GET ON THE CONTACT<br />

POINTS AND CAUSE BURNING.<br />

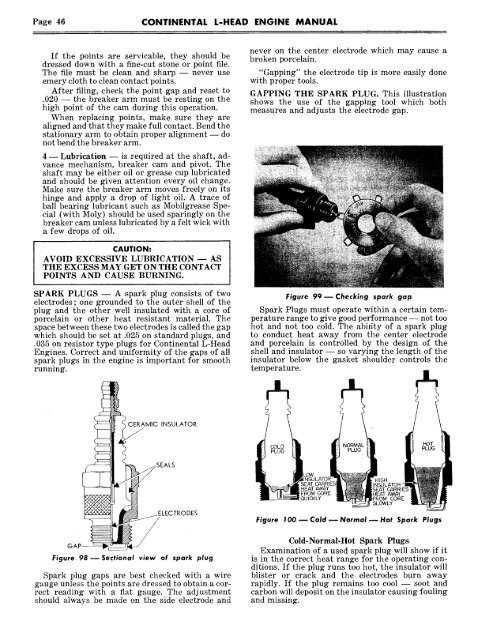

SPARK PLUGS -- A spark plug consists of two<br />

electrodes; one grounded to the outer shell of the<br />

plug and the other well insulated with a core of<br />

porcelain or other heat resistant material. The<br />

space between these two electrodes is called the gap<br />

which should be set at .025 on standard plugs, and<br />

.035 on resistor type plugs for <strong>Continental</strong> L-<strong>Head</strong><br />

Engines. Correct and uniformity of the gaps of all<br />

spark plugs in the engine is important for smooth<br />

running.<br />

GAP--<br />

CERAMIC INSULATOR<br />

~ -SEALS<br />

LECTRODES<br />

Figure 98 ~ Sectional view of spark plug<br />

Spark plug gaps are best checked with a wire<br />

gauge unless the points are dressed to obtain a correct<br />

reading with a flat gauge. The adjustment<br />

should always be made on the side electrode and<br />

never on the center electrode which may cause a<br />

broken porcelain.<br />

"Gapping" the electrode tip is more easily done<br />

with proper tools.<br />

GAPPING THE SPARK PLUG. This illustration<br />

shows the use of the gapping tool which both<br />

measures and adjusts the electrode gap.<br />

Figure 9Om Checking spark gap<br />

Spark Plugs must operate within a certain temperature<br />

range to give good performance -- not too<br />

hot and not too cold. The abidty of a spark plug<br />

to conduct heat away from the center electrode<br />

and porcelain is controlled by the design of the<br />

shell and insulator -- so varying the length of the<br />

insulator below the gasket shoulder controls the<br />

temperature.<br />

COLD<br />

PLUG<br />

HEAT AWAY<br />

FROM OORE HEAT AWAY<br />

FROM CORE<br />

SLOWLY<br />

Figure 100 ~ Cold ~ Normal ~ Hot Spark Plugs<br />

Cold-Normal-Hot Spark Plugs<br />

Examination of a used spark plug will show if it<br />

is in the correct heat range for the operating conditions.<br />

If the plug runs too hot, the insulator will<br />

blister or crack and the electrodes burn away<br />

rapidly. If the plug remains too cool -- soot and<br />

carbon will deposit on the insulator causing fouling<br />

and missing.