Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Continental L-Head Overhaul Manual - Igor Chudov

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 60 CONTINENTAL L-HEAD ENGINE MANUAL<br />

Pistons are cam and taper ground, and this must<br />

be taken into consideration when checking alignment<br />

of the assembly, since the diameter in line<br />

with the piston pin would be less at the top of the<br />

skirt than at the bottom.<br />

Figure 134--Checking connecting rod assembly<br />

for alignment<br />

PISTON RINGS<br />

Check the piston rings in the cylinders for gap.<br />

To do this, insert a piston in the cylinder bore<br />

in an inverted position and then insert each ring<br />

one at a time about 2" down in the bore and bring<br />

the bottom edge of the piston up against the ring<br />

to square it up in the cylinder bore.<br />

Check the gap between the ends of the ring with<br />

a feeler gauge in accordance with specificatie, ns<br />

shown in the Limits and Clearance chart.<br />

RECOMMENDED METHOD OF INSTALLING<br />

PISTON RINGS<br />

1. Grip the connecting rod in a vise with lead<br />

lined jaws to hold the piston firmly and roll each<br />

of the straight side rings in its groove to be sure<br />

there are no burrs or other interference with the<br />

free action of the ring in the groove.<br />

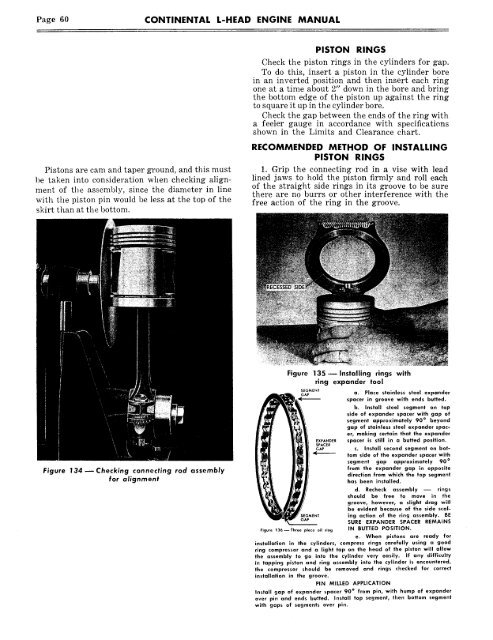

Figure 135- Installing rings with<br />

ring expander tool<br />

SEGMENT<br />

a~<br />

~<br />

a. Place stainless steel expander<br />

spacer in groove with ends butted.<br />

b. Install steel segment on top<br />

~<br />

side of expander spacer with gap of<br />

segment approximately 90 ° ~<br />

beyond<br />

gap of stainless steel expander spacer,<br />

making certain that the expander<br />

spacer is still in a butted position.<br />

c. Install second segment on botlom<br />

side of the expander spacer with<br />

segment<br />

°<br />

gap approximately 90<br />

from the expander gap in opposite<br />

direction from which the top segment<br />

has been installed.<br />

d. Recheck assembly ~ rings<br />

should be free to move in the<br />

groove, however, a slight drag will<br />

~<br />

be evident because of the side scaling<br />

action of the ring assembly. BE<br />

SURE EXPANDER SPACER REMAINS<br />

Figure 136--Three piece oil ring IN BUTTED POSITION.<br />

e. When pistons are ready for<br />

installation in the cylinders, compress rings carefully using a good<br />

ring compressor and a light tap on the head of the piston will allow<br />

the assembly to go into the cylinder very easily. If any difficulty<br />

in tapping piston and ring assembly into the cylinder is encountered,<br />

the compressor should be removed and rings checked for correct<br />

installation in the groove.<br />

PIN MILLED APPLICATION<br />

Install gap of expander spacer 90 ° from pin, with hump of expander<br />

over pin and ends butted. Install top segment, then bottom segment<br />

with gaps of segments over pin.